When choosing between double row angular contact bearing, angular contact double row ball bearing, and double row angular ball bearing, it’s essential to understand the role each plays in supporting loads, maintaining precision, and increasing the reliability of mechanical systems. These bearing types are foundational in industries ranging from robotics to automotive, and the differences between them go far beyond just their appearance. In this guide, we break down key differences, advantages, and how to decide which bearing fits your specific needs. Know More

What Are Angular Contact Bearings?

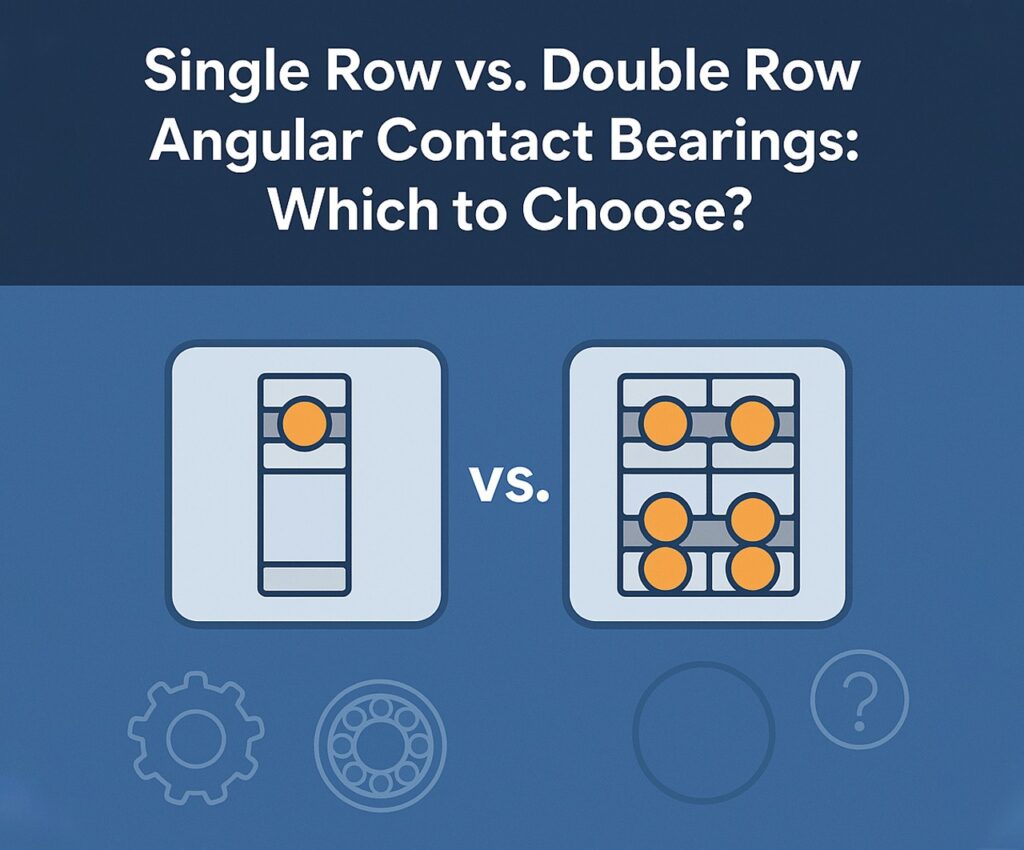

Angular contact bearings are designed to handle both radial and axial loads. The contact angle—typically ranging from 15° to 40°—allows the bearing to support higher axial loads compared to standard radial bearings. A double row angular contact bearing essentially combines two single row angular contact bearings back-to-back in one unit. This configuration increases load capacity and rigidity.

A double row angular ball bearing provides the benefit of handling axial loads in both directions while maintaining compactness. Meanwhile, the angular contact double row ball bearing enhances performance in high-speed applications due to its symmetrical load handling capability.

Core Differences: Single vs. Double Row

Single Row Angular Contact Bearings

- Designed to support axial loads in one direction only.

- Require a second bearing to balance axial forces.

- Offer higher speed capabilities due to lighter construction.

- Suitable for applications where space is tight but axial load is predictable.

Double Row Angular Contact Bearings

- Handle axial loads in both directions.

- More rigid due to their dual-row construction.

- Can replace two single row bearings mounted in opposition.

- Take up slightly more space but simplify assembly and reduce alignment complexity.

In applications where axial load direction changes or high radial and axial loads exist simultaneously, a double row angular contact bearing is often the smarter choice.

When to Use Double Row Angular Contact Bearings

A double row angular ball bearing is ideal when your design requires robust axial and radial load support without adding extra components. They’re often used in:

- Electric motors

- Machine tool spindles

- Pumps and compressors

- Gearboxes

Thanks to their symmetry, angular contact double row ball bearing setups reduce misalignment risk and increase installation efficiency. Their built-in opposing races eliminate the need for matched bearing pairs, saving both time and money during setup.

When to Use Single Row Angular Contact Bearings

Single row variants shine in high-speed applications where directional axial loads are known. They allow designers to place bearings strategically in complex assemblies.

Typical applications include:

- Automotive gearboxes

- Turbines

- Precision instruments

- Clutches

If your machinery experiences axial loads in only one direction, a single row bearing is lighter and often more cost-effective. But when axial load shifts direction or varies in intensity, upgrading to a double row angular contact bearing helps ensure long-term performance.

Load Capacity Considerations

A double row angular ball bearing naturally supports higher loads due to its dual-path contact system. It’s particularly beneficial in applications involving sudden load changes or vibration.

However, the trade-off is speed. A single row unit, being lighter, typically supports higher RPMs. For applications where rotational speed is prioritized over load capacity, this difference can be decisive.

Angular contact double row ball bearing solutions strike a balance, offering better-than-single-row load capacity without severely compromising speed.

Axial Rigidity and Alignment

Double row angular contact bearing types improve system stiffness. In CNC machines, for example, rigidity is crucial for maintaining cutting precision under fluctuating forces. A double row angular ball bearing enhances axial rigidity, especially where shaft deflection could degrade accuracy.

The angular contact double row ball bearing configuration maintains consistent axial and radial alignment, reducing the risk of premature wear due to shaft misalignment or housing imperfections.

Temperature and Lubrication Factors

Double row bearings often run slightly hotter due to increased contact surfaces. This requires attention to lubrication. Grease or oil-lubricated double row angular ball bearing units need proper flow to avoid overheating and maintain performance.

If your system runs at elevated temperatures or for long cycles, consult manufacturers for recommended grease types and service intervals. For extremely high speeds, a single row variant may be more suitable, especially when paired with advanced ceramic materials.

Installation and Space Efficiency

A key advantage of the angular contact double row ball bearing is its simplicity. One component does the job of two single row bearings, which means:

- Fewer parts

- Easier alignment

- Faster installation

However, if your design has very limited radial space, a pair of single row bearings in a tailored housing might still be your best bet. Assess your layout constraints before finalizing the bearing type.

Cost-Benefit Analysis

A double row angular contact bearing might seem more expensive upfront, but it reduces assembly time, lowers misalignment risk, and increases system reliability. Over the life of a machine, these savings often outweigh the initial cost difference.

On the other hand, single row bearings allow more modular design and easier sourcing. If your team prefers off-the-shelf components or frequently services equipment in the field, this flexibility can be a plus.

Angular contact double row ball bearing models offer a sweet spot: factory-paired performance with less overhead.

Industry Use Cases

- Aerospace: Lightweight single row bearings for control surfaces and actuators.

- Industrial Machinery: Double row angular ball bearing options for gearboxes and spindles.

- Renewable Energy: Double row angular contact bearing setups in wind turbines, supporting multi-directional forces.

- Medical Devices: Precision single row bearings where load direction is known and speed is key.

Future Developments

Manufacturers are investing in hybrid designs, integrating ceramic balls and new cage materials. The goal is to produce double row angular contact bearing units with the speed benefits of single row bearings.

Expect to see more intelligent bearings soon—with embedded sensors that track wear, misalignment, and lubrication status in real time. In high-demand industries, these angular contact double row ball bearing innovations will drive better uptime and predictive maintenance.

Final Thoughts

Choosing between single row and double row angular contact bearing types depends on your application’s specific demands. If you need high load capacity, built-in axial rigidity, and simplified setup, go with the angular contact double row ball bearing. For high-speed, directional-load environments where space is tight, stick with a single row solution.

Remember, each machine is unique. Analyze load conditions, speed requirements, and design constraints before making the call. And when in doubt, consult manufacturers offering a range of double row angular ball bearing products—they often provide valuable technical insights that can make or break a design.

Whichever path you choose, smart bearing selection is key to smoother motion, longer life, and fewer maintenance headaches.