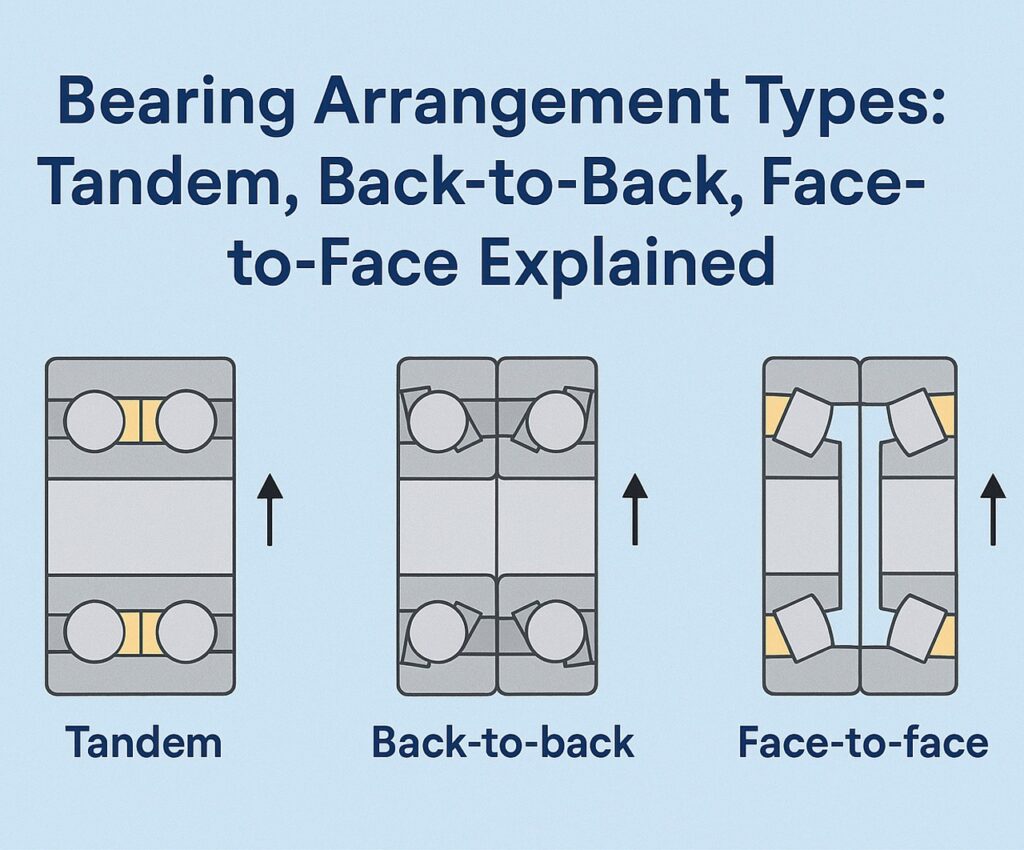

When it comes to optimizing load distribution and system stability, the right bearing arrangement can make all the difference. Whether you’re working with miniature angular contact bearings, specifying sealed angular contact bearings for a high-contamination environment, or adjusting the angular contact ball bearing angle to control thrust load behavior, understanding tandem, back-to-back, and face-to-face configurations is essential. These arrangements define how paired bearings share loads, manage misalignment, and perform under combined stresses.

This article breaks down the fundamentals of bearing arrangement types, explores when to use each, and explains how design choices impact system dynamics, especially when precision and durability are non-negotiable. Know More

Why Bearing Arrangement Matters

Bearings are often used in pairs or sets when a single bearing can’t meet load, alignment, or precision requirements alone. The way these bearings are mounted—known as their arrangement—determines how they respond to axial and radial forces, thermal expansion, and shaft deflection.

The angular contact ball bearing angle directly affects how a bearing handles axial loads. A steeper angle allows better axial support, and when these bearings are paired correctly, the system gains increased stiffness, load capacity, and resistance to misalignment.

1. Tandem Arrangement

In a tandem configuration, bearings are mounted side-by-side with their contact angles pointing in the same direction. This arrangement is designed to share axial loads in one direction.

Features:

- Increased axial load capacity in one direction

- Typically used with a third bearing to support axial loads in the opposite direction

- Often found in high-thrust applications like vertical pumps and screw drives

Best for:

- Linear actuators

- Ball screw support

- Gearbox input shafts

When using miniature angular contact bearings in tandem, precise preload setting is critical to ensure equal load sharing.

2. Back-to-Back Arrangement (DB Arrangement)

Also called an “O” arrangement, back-to-back mounting places bearings with contact angles diverging away from each other. This forms a wide load zone and gives the system high rigidity.

Advantages:

- Supports axial loads in both directions

- Excellent for handling moments and shaft tilting

- Ideal for applications with heavy radial loads

Applications:

- CNC spindle assemblies

- Precision machine tool drives

- Automotive differential carriers

Sealed angular contact bearings are commonly used in back-to-back pairs in contaminated environments, as their positioning helps protect against the ingress of dirt and moisture.

3. Face-to-Face Arrangement (DF Arrangement)

In the face-to-face or “X” arrangement, the contact angles converge inward toward the bearing centerline. This setup accommodates shaft misalignment better than back-to-back.

Key Benefits:

- Handles axial loads in both directions

- More tolerant of angular misalignment

- Preferred in cases where shaft or housing deformation is expected

Common Uses:

- Fan shafts

- Conveyor rollers

- Precision actuators

When working with sealed angular contact bearings, the face-to-face setup is often chosen for compact assemblies where ease of installation and better misalignment compensation are priorities.

Choosing the Right Arrangement for Your Application

Your selection depends on several design criteria:

Axial Load Direction

- Use tandem when loads are unidirectional and heavy

- Use back-to-back for bidirectional axial loads and moment resistance

- Use face-to-face for bidirectional loads with misalignment concerns

Misalignment Tolerance

- Face-to-face provides the most flexibility

- Back-to-back is less forgiving but offers greater system rigidity

Available Space

- Face-to-face has a narrower spread, making it better for compact assemblies

- Back-to-back occupies more axial space but offers greater support

Preload and Rigidity

- Back-to-back delivers superior stiffness when preloaded

- Tandem enhances load capacity without increasing system stiffness too much

Importance of Angular Contact Ball Bearing Angle

The angular contact ball bearing angle is the angle between the line joining the points of contact of the ball and raceway and a line perpendicular to the bearing axis. Common angles are 15°, 25°, and 40°.

- 15° to 25°: Preferred for high-speed applications

- 40° and above: Used for higher axial loads

Pairing bearings with matching or complementary angles ensures optimal load sharing and smooth performance. When using miniature angular contact bearings, smaller angles are more typical to support precise rotation at high speeds.

Sealed Angular Contact Bearings: Special Considerations

Sealed angular contact bearings are increasingly popular due to:

- Reduced maintenance needs

- Protection against contaminants

- Longer service intervals

When arranging sealed pairs:

- Always align seals outward if protection is a priority

- Use inward-facing seals in lubricant retention-focused applications

These configurations are common in food processing, electric motor spindles, and semiconductor manufacturing.

Installation and Preload Tips

Proper mounting and preload are essential for achieving the intended benefits of each bearing arrangement.

Tips:

- Ensure shaft and housing seats are precisely machined

- Use shims or preload springs for tandem sets

- Apply axial tightening torque evenly

- Check for axial displacement under load during testing

Preload should be calculated based on:

- Operating speed

- Thermal expansion characteristics

- Load conditions

Real-World Applications

- Miniature angular contact bearings in drones and surgical tools benefit from face-to-face mounting for vibration resistance

- Sealed angular contact bearings in wind turbine gearboxes use back-to-back setups to maximize durability

- Machine tools employ tandem arrangements to manage long thrust loads from cutting operations

Final Thoughts

Understanding and selecting the right bearing arrangement type is a critical part of machine design. Whether you need the compact precision of miniature angular contact bearings, the protection of sealed angular contact bearings, or the performance boost from dialing in your angular contact ball bearing angle, how you mount and align your bearings matters.

Tandem, back-to-back, and face-to-face configurations each offer unique advantages depending on your application’s load, space, and precision demands. Mastering these fundamentals ensures longer machine life, smoother operation, and fewer surprises during maintenance cycles.