Tapered roller bearings are the unsung heroes behind heavy-duty motion systems, whether in industrial transport, precision equipment, or automotive drivetrains. As more applications demand durability and precision, innovations like the tapered roller conveyor, ceramic tapered roller bearings, and metric tapered roller bearings are redefining performance expectations. In this article, we’ll explore the anatomy of a tapered roller bearing, its working principle, and how modern variations are engineered for today’s demanding industries. Know More

What Is a Tapered Roller Bearing?

A tapered roller bearing is a rolling element bearing that uses conical rollers to support both axial and radial loads. Its design allows it to accommodate higher load capacities compared to ball bearings, and it excels in applications where alignment and stability are critical.

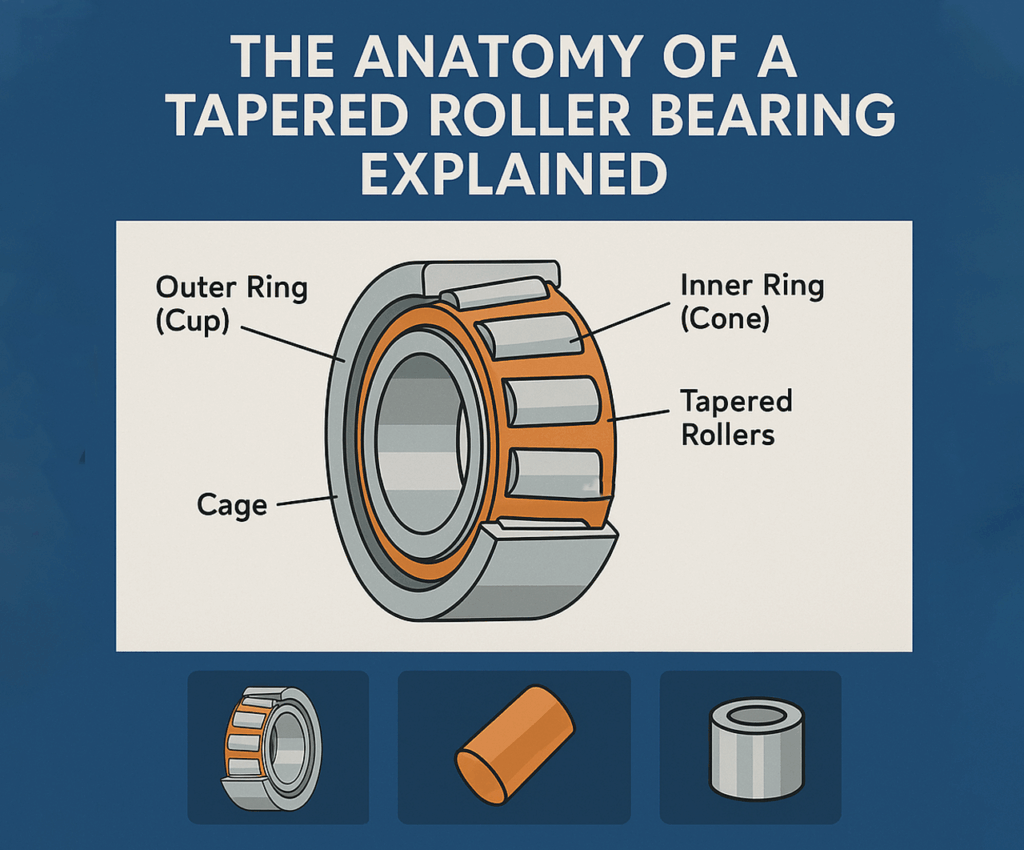

Key Components of a Tapered Roller Bearing:

- Inner Ring (Cone): Fits on the shaft and rotates with it.

- Outer Ring (Cup): Fixed within the housing.

- Tapered Rollers: The conical rolling elements that carry the load.

- Cage (Retainer): Maintains even spacing of rollers to prevent contact and friction.

This geometry allows the bearing to handle combined radial and thrust loads, a reason why the tapered roller conveyor and transport systems often use them in high-load, high-speed scenarios.

The Function of Each Component

Inner Ring (Cone)

It’s precision-machined to fit tightly onto a shaft. The inner raceway is angled to guide the rollers towards the axis, ensuring efficient load transfer.

Outer Ring (Cup)

Secured in the housing, the cup provides the counter-raceway for the rollers, aligning with the cone’s angle to create a shared rolling path.

Tapered Rollers

These rolling elements are what make the bearing unique. Their tapered shape helps evenly distribute load across the roller’s length, minimizing stress concentrations.

Cage

The cage holds the rollers in place and ensures proper spacing. In high-speed or high-temperature applications like ceramic tapered roller bearings, the cage must be engineered for stability and minimal wear.

Load Capabilities and Performance

Tapered roller bearings are capable of handling:

- Radial loads (perpendicular to the shaft)

- Axial loads (parallel to the shaft)

- Shock loads (sudden, high-intensity forces)

This tri-capability makes them indispensable in:

- Automotive wheel hubs

- Gearboxes

- Tapered roller conveyor rollers

- Agricultural and construction machinery

Metric tapered roller bearings are standardized under ISO dimensions, enabling consistent performance across global OEMs and maintenance sectors.

Variants of Tapered Roller Bearings

1. Single-Row Bearings

Ideal for applications where combined load needs are moderate. These require preload adjustments during installation to ensure optimal performance.

2. Double-Row Bearings

Capable of handling heavy radial and axial loads in both directions. Common in heavy vehicles and conveyor systems.

3. Four-Row Bearings

Used in rolling mills and high-load industrial applications. These provide stability in rotational equipment under intense load.

4. Ceramic Tapered Roller Bearings

An innovation for high-speed, low-friction environments. Made with silicon nitride rollers and steel races, ceramic tapered roller bearings offer:

- High-temperature resistance

- Corrosion protection

- Lower rotational inertia

They’re favored in aerospace, electric vehicles, and advanced robotics.

5. Metric Tapered Roller Bearings

Interchangeable and globally available, these are defined by ISO dimensions, offering versatility and reduced procurement complexity.

Tapered Roller Conveyor Applications

In industrial material handling, the tapered roller conveyor is a type of curved conveyor that uses tapered rollers to maintain consistent spacing between packages as they move through bends.

Why Use Tapered Bearings in Conveyors?

- Supports dynamic weight as loads shift through curves

- Provides stability and load uniformity

- Handles the constant axial and radial forces in high-throughput facilities

Combined with metric tapered roller bearings, conveyor manufacturers can design systems that are both modular and maintenance-friendly.

Advantages of Tapered Roller Bearings

- Load Versatility: Can handle both radial and axial loads with ease.

- Durability: Robust under shock and continuous loads.

- Alignment Capabilities: Maintains alignment under load.

- Customizable Fit: Preload can be adjusted for precision or clearance.

- Standardization: Especially with metric tapered roller bearings, ease of replacement and global sourcing is simplified.

Disadvantages and Considerations

- Preload Sensitivity: Improper preload can reduce life or increase friction.

- Space Requirements: Larger than comparable ball bearings.

- Lubrication Needs: Must be adequately lubricated to prevent overheating or wear.

- Installation Complexity: More precise alignment and torque settings required.

Ceramic tapered roller bearings may mitigate some of these issues by running cooler and lasting longer, albeit at a higher cost.

Lubrication and Maintenance

Tapered bearings require proper lubrication to:

- Minimize wear

- Prevent corrosion

- Maintain smooth motion

In high-speed applications like ceramic tapered roller bearings, synthetic greases or oil-mist systems are preferred. For tapered roller conveyor systems in dusty environments, sealed bearing options reduce contamination and downtime.

Selection Tips for Engineers

- Load Direction: Choose a configuration based on axial vs. radial dominance.

- Speed: High-speed systems may benefit from ceramic tapered roller bearings.

- Environment: For harsh or wet conditions, opt for sealed or corrosion-resistant models.

- Dimensions: Use metric tapered roller bearings for easy replacements worldwide.

- Maintenance Access: For low-maintenance designs, consider pre-lubricated or sealed options.

Future Trends in Tapered Roller Bearings

- Sensor Integration: Bearings embedded with temperature and vibration sensors for predictive maintenance.

- Advanced Coatings: DLC and ceramic coatings to enhance life in extreme environments.

- Hybrid Designs: Combining ceramic tapered roller bearings with smart materials for self-monitoring performance.

- Modular Bearings: Pre-assembled units for quick installation in tapered roller conveyor systems.

Final Thoughts

Tapered roller bearings are more than just mechanical support—they’re precision instruments vital to modern industry. From automotive to aerospace and from tapered roller conveyor systems to robotics, these bearings must perform reliably under stress.

Whether you’re seeking longevity, high-speed stability, or global standardization through metric tapered roller bearings, or looking to explore advanced ceramic tapered roller bearings, understanding their anatomy is the first step to making smarter design and maintenance decisions.

With innovations continually reshaping bearing performance, the future is tapered—and it’s rolling in faster than ever.