In high-performance applications ranging from industrial equipment to sports gear, ceramic bearings have gained massive popularity. Whether you’re an engineer optimizing for speed and durability or a skater searching for the smoothest ride, knowing the difference between full ceramic and hybrid ceramic bearings matters. For example, when choosing skateboard ceramic bearings, comparing a bearing ceramic 608 with a bearing hybrid ceramic can completely change your setup’s feel, longevity, and speed. In this guide, we break down the core differences, benefits, and best use cases so you can make the right call for your needs. Know More

What Are Ceramic Bearings?

Ceramic bearings are precision components that use ceramic materials (most commonly silicon nitride or zirconia) for rolling elements and sometimes for races. They’re known for their:

- Low friction

- High-speed performance

- Corrosion resistance

- Long lifespan

There are two main types:

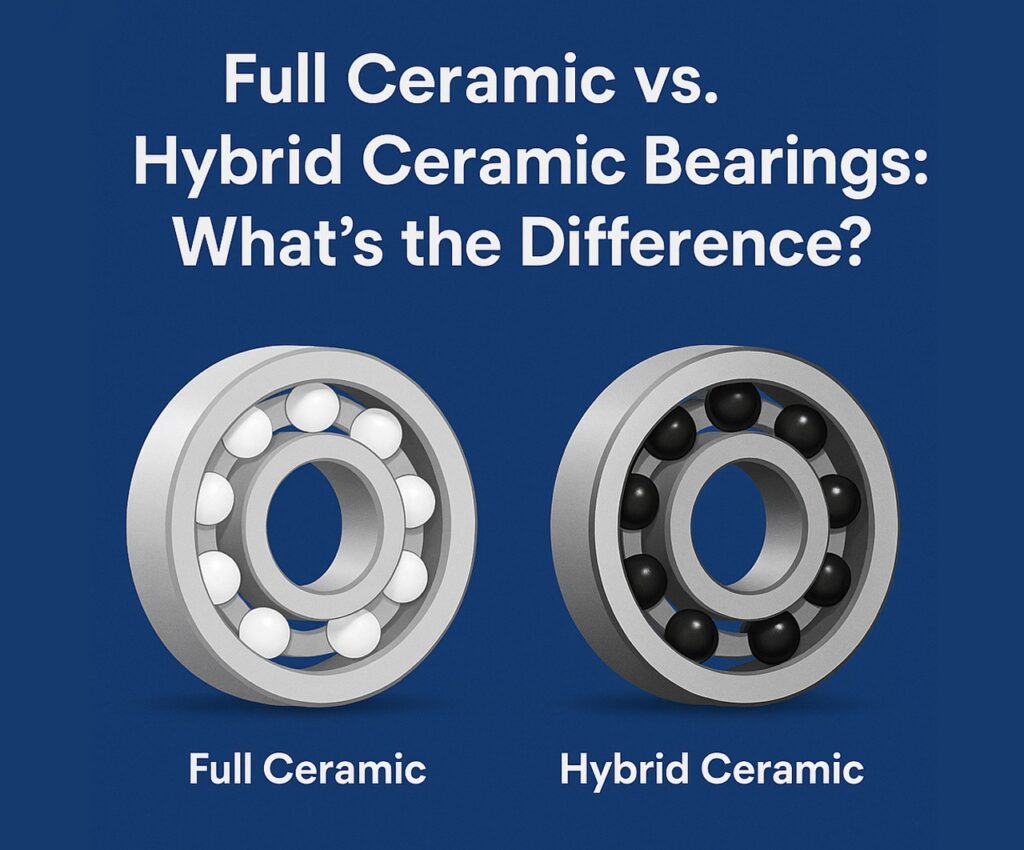

- Full Ceramic Bearings: Both the balls and races are made entirely from ceramic.

- Hybrid Ceramic Bearings: Ceramic balls are paired with steel races (usually stainless or chrome steel).

Understanding the structural and performance differences between these two options is key—especially in industries or sports where micro-advantages have macro consequences.

The Basics of Full Ceramic Bearings

Full ceramic bearings are made entirely of ceramic material. They’re lightweight, non-conductive, corrosion-resistant, and can run dry without lubrication.

Core Benefits:

- Ultra-low friction: Ideal for high-speed applications

- Non-magnetic and non-conductive: Excellent for sensitive electronics

- Corrosion-resistant: Great in chemical and underwater environments

Example Use Case: A custom motor running in a corrosive lab environment where lubrication is limited. Full ceramic bearings will outlast steel or hybrid options while maintaining performance.

Drawbacks:

- Higher cost

- Brittle under heavy impact

- Less forgiving under high shock or misalignment

That’s why full ceramics aren’t the go-to for all use cases—even if they sound superior on paper.

The Case for Hybrid Ceramic Bearings

A bearing hybrid ceramic uses ceramic balls with steel races. This combo gives you many of the benefits of ceramic (like lower weight and friction) while maintaining the durability and toughness of steel.

Advantages:

- More impact-resistant than full ceramics

- Lower cost while retaining performance gains

- Easier to manufacture and widely available

Common Example: Skateboard ceramic bearings often use hybrid configurations. The ceramic balls reduce friction and improve acceleration, while the steel races stand up to high jumps, uneven pavement, and impact.

Downsides:

- Not fully corrosion-resistant

- Can require more maintenance than full ceramics in harsh environments

If you’re buying a bearing ceramic 608 for inline skates or electric skateboards, odds are it’s a hybrid—optimized for balance.

Comparing Full Ceramic and Hybrid Ceramic Bearings

| Feature | Full Ceramic | Hybrid Ceramic |

| Material | Ceramic balls & races | Ceramic balls + steel races |

| Speed | Higher | Very high |

| Durability | Excellent (except under shock) | High (better under impact) |

| Corrosion Resistance | Superior | Moderate (steel can corrode) |

| Cost | Higher | Moderate |

| Lubrication | Often not needed | Recommended for best performance |

| Use Case Highlight | Chemical labs, cleanrooms | Sports, robotics, general industry |

Spotlight: Bearing Ceramic 608 in Action

The bearing ceramic 608 designation refers to a common size used in:

- Skateboards

- Inline skates

- 3D printers

- Small motors

Choosing between a full ceramic vs. bearing hybrid ceramic version of the 608 comes down to your environment and usage intensity.

Use a full ceramic 608 bearing if:

- You need corrosion resistance (e.g., in wet or marine settings)

- Noise reduction and non-conductivity are priorities

Use a hybrid ceramic 608 bearing if:

- You want to upgrade performance in sports like skating or scootering

- You need good impact resistance and affordability

What About Skateboard Ceramic Bearings?

Skateboard ceramic bearings are almost always hybrid. Why?

- Skating involves impacts, drops, and vibration

- Full ceramic bearings may crack under sudden force

However, ceramic balls still improve:

- Acceleration

- Top-end speed

- Resistance to dirt and corrosion (when sealed properly)

Premium brands market ceramic skateboard bearings for competitive riders looking for smooth, high-RPM performance. Just know that proper installation and regular cleaning matter just as much as the material.

The Role of Lubrication

While full ceramic bearings can technically run dry, that doesn’t mean they should. Proper lubrication still helps reduce friction, lower noise, and extend life—especially in hybrid ceramic types.

Dry environments: Full ceramic may excel if oil contamination is a concern. High-load environments: Hybrid ceramic should be greased for protection.

In skateboarding or biking, light oil (like Bones Speed Cream) is commonly used for skateboard ceramic bearings to maintain speed without attracting dirt.

How to Choose Based on Application

Ask yourself:

- Will the bearing face impact or shock loads?

- Is corrosion resistance critical?

- What RPM and torque will it experience?

- Is this a precision tool or a sport application?

- What is the expected lifespan vs. budget?

For recreational use, a bearing hybrid ceramic offers an excellent balance. For medical tools or lab robotics, full ceramics may be worth the investment.

Maintenance and Care Tips

To get the most out of your ceramic bearings:

- Clean regularly using isopropyl alcohol

- Re-lubricate with compatible oils or greases

- Avoid over-tightening spacers or axles

- Store in dry, dust-free environments

Hybrid skateboard ceramic bearings can last multiple seasons with good maintenance. Full ceramic options can last even longer in controlled settings.

Final Thoughts

So, which is better: full ceramic or hybrid ceramic bearings? It all depends on your needs.

- Choose full ceramic if your priority is corrosion resistance, non-conductivity, and extreme conditions with low shock.

- Choose hybrid ceramic if you want high-speed, impact-friendly performance at a more affordable cost.

Whether you’re selecting bearing ceramic 608 for a 3D printer, upgrading to skateboard ceramic bearings, or exploring a custom bearing hybrid ceramic design for a robotics project, understanding the differences empowers better performance and smarter investment.