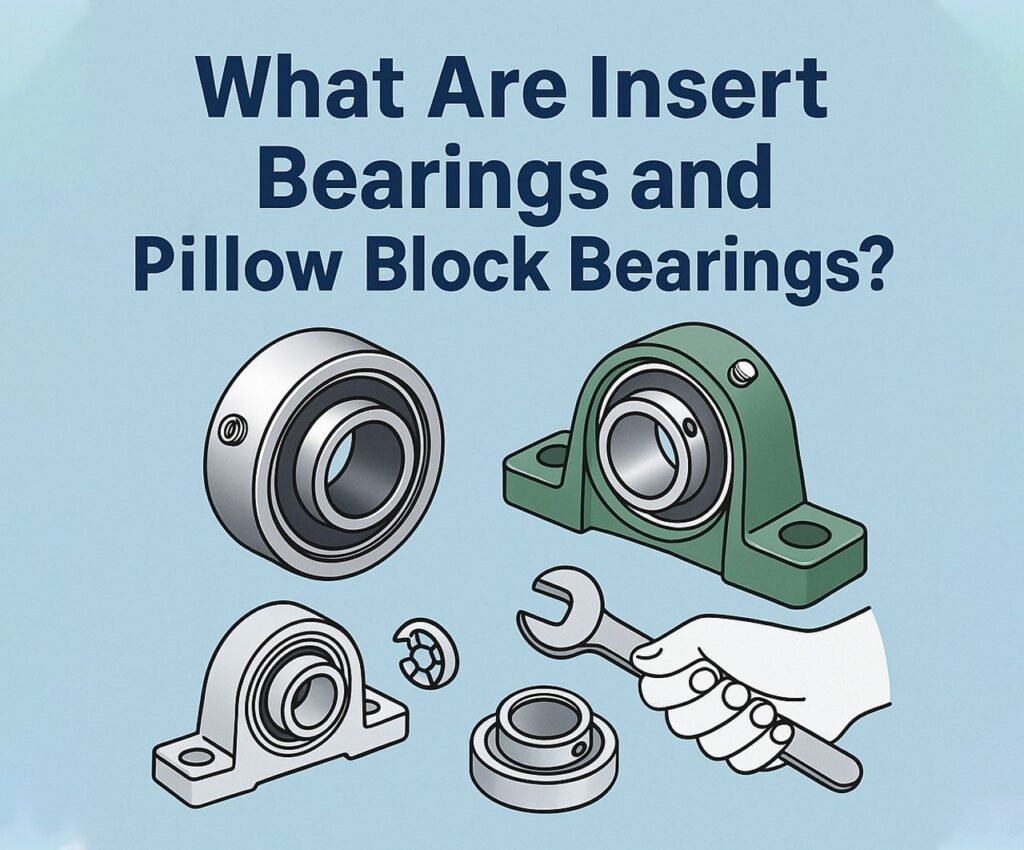

When it comes to simple yet effective bearing units, insert bearings, insert ball bearing assemblies, and pillow block bearings are among the most versatile and commonly used components in industrial design. Found in everything from conveyor systems to agricultural machinery, these bearings are designed for reliability, ease of installation, and adaptability to rough environments. This article dives into what they are, how they function, and why they matter in both everyday machinery and specialized applications. Know More

Understanding Insert Bearings

Insert bearings are self-contained bearing units that consist of a deep groove ball bearing with an extended inner ring and a specific locking mechanism. A typical insert ball bearing is pre-lubricated, sealed, and ready to install, offering both convenience and performance.

What makes insert bearings unique is their ability to be mounted easily into housings (such as pillow block bearings) with minimal effort. They are commonly used in scenarios where reliability, low maintenance, and moderate speeds are essential.

Construction of Insert Ball Bearings

A standard insert ball bearing features:

- Deep groove ball bearing core

- Extended inner ring for better shaft support

- Sealing elements to retain lubricant and exclude contaminants

- Locking mechanisms like set screws or eccentric collars to fix the bearing to a shaft

These features make insert bearings suitable for a wide range of shaft tolerances and operating conditions.

Introduction to Pillow Block Bearings

Pillow block bearings, also known as housed bearings or plummer blocks, are mountable bearing units designed to support a rotating shaft. They are composed of a housing—usually cast iron or pressed steel—and a replaceable insert ball bearing mounted within.

The housing of pillow block bearings is engineered to be bolted to a surface, allowing for stable support and easy replacement of the insert. The modular design means that if the bearing fails, the housing remains intact and only the insert bearing needs replacing.

Key Features of Pillow Block Bearings

- Pre-assembled units: Quick installation

- Sealed and lubricated: Low maintenance needs

- Durable housings: Designed for rugged environments

- Replaceable inserts: Cost-effective maintenance

This simplicity and adaptability are why pillow block bearings are found across so many industries.

How Insert Bearings and Pillow Block Bearings Work Together

Think of insert bearings as the functional core and pillow block bearings as the housing that protects and positions them. The insert ball bearing slides into the pillow block and is locked in place using set screws or eccentric collars. The result is a bearing system that:

- Absorbs radial and limited axial loads

- Allows for minor shaft misalignments

- Handles shock and vibration effectively

This configuration is especially useful for applications where the shaft isn’t perfectly aligned or where system vibration is common.

Applications of Insert Bearings and Pillow Block Bearings

You’ll find insert bearings and pillow block bearings across a wide range of industries:

- Agriculture: Harrows, balers, seeders

- Material Handling: Conveyors, rollers, belt drives

- HVAC Systems: Fans, blowers, and duct motors

- Food Processing: Stainless steel variants for hygiene compliance

- Construction: Cement mixers, crushers, compactors

Whether dealing with dirt, moisture, or constant motion, these bearing units hold up under pressure.

Locking Mechanisms Explained

One of the standout features of insert ball bearing units is their shaft locking method. Common types include:

- Set Screw Locking: Two screws clamp the bearing to the shaft. Best for low to medium loads.

- Eccentric Locking Collar: A cam-shaped collar that rotates to grip the shaft. Common in agricultural equipment.

- Adapter Sleeve Mounting: Often used in heavy-duty applications where vibration is a concern.

These options allow insert bearings to be installed quickly and securely, even in less-than-ideal conditions.

Advantages of Insert Bearings

- Ready to use: Pre-lubricated and sealed

- Versatile: Compatible with multiple housing types

- Shock resistant: Handles rough environments

- Flexible mounting: Various shaft-locking methods available

These qualities make insert ball bearing solutions ideal for dynamic and demanding mechanical systems.

Benefits of Pillow Block Bearings

- Easy replacement: Swap out the insert without disassembling the system

- Long lifespan: Durable housing material protects the bearing

- Mounting flexibility: Bolts easily to various surfaces

- Cost-effective: Reduced downtime during maintenance

Together, insert bearings and pillow block bearings form a powerful, user-friendly bearing solution.

Materials and Coatings

Both insert bearings and pillow block bearings come in various materials and finishes:

- Cast Iron: Common for general industrial use

- Stainless Steel: Corrosion-resistant, ideal for food and pharma

- Thermoplastic Housings: Lightweight and hygienic

- Coated Steel: For environments with high humidity or chemicals

This variety ensures that every insert ball bearing application has a suitable housing to match its environment.

Maintenance Tips

- Lubricate periodically: Even pre-lubricated bearings may need grease over time

- Inspect seals: Replace when damaged to keep contaminants out

- Check alignment: Misalignment can cause early failure

- Monitor noise and vibration: These are often early signs of wear

Proper care extends the life of both insert bearings and pillow block bearings, ensuring smooth, uninterrupted operation.

Innovations and Trends

As technology evolves, so do insert ball bearing systems. Some emerging trends include:

- Sensor-integrated bearings: Real-time data on temperature, vibration, and load

- Grease-free variants: For cleaner operation in food-grade systems

- Modular designs: Quick-swap units for rapid maintenance

- Smart housings: Coated with antimicrobial layers for healthcare use

These advancements help modern pillow block bearings meet the rising demands of Industry 4.0 environments.

Choosing the Right Bearing Unit

To choose the right insert bearings and pillow block bearings, consider:

- Load requirements: Both radial and axial

- Speed of operation: Match with appropriate sealing and lubrication

- Environmental conditions: Moisture, dust, heat, or chemicals

- Installation space: Compact designs may be required

Manufacturers typically provide detailed load and speed ratings, so consult technical specs to ensure compatibility.

Conclusion

Insert bearings and pillow block bearings offer a dependable, flexible, and low-maintenance solution for a wide range of mechanical systems. With their ease of installation, robust design, and adaptability, they are a staple in both light-duty and heavy-duty applications.

Whether you’re building a conveyor or upgrading a fan assembly, pairing a quality insert ball bearing with the right housing will keep your machines running smoothly, even in harsh conditions. As industries move toward smarter, more integrated systems, expect even more innovation in the world of pillow block bearings and insert technologies.