In heavy machinery, automation systems, and high-load mechanical assemblies, the correct installation of spherical bearings is crucial to performance and reliability. Whether you’re dealing with an axial spherical roller bearing, a bearing roller spherical type, or a double row self aligning spherical roller bearing, even the highest-quality component can fail prematurely if mounted incorrectly. In this article, we’ll walk through the essential do’s and don’ts of mounting spherical bearings—and why these guidelines matter more than you think. Know More

Understanding the Bearing Types

Before diving into mounting procedures, it’s important to know what you’re working with:

- An axial spherical roller bearing supports axial loads in one direction and can handle slight misalignments.

- A bearing roller spherical handles both radial and axial loads, thanks to its barrel-shaped rollers and self-aligning properties.

- The double row self aligning spherical roller bearing consists of two rows of rollers, providing excellent load distribution and the ability to compensate for shaft deflection or housing misalignment.

Each of these bearing types is designed to perform under heavy stress, but improper mounting can negate their built-in advantages.

DO: Inspect the Components Before Assembly

Before you mount any bearing roller spherical type, thoroughly inspect the shaft, housing, and the bearing itself. Look for:

- Surface damage or scoring

- Burrs, dents, or contamination

- Out-of-round or misaligned bores

Clean everything meticulously. Even small debris can create uneven load distribution, which leads to early failure.

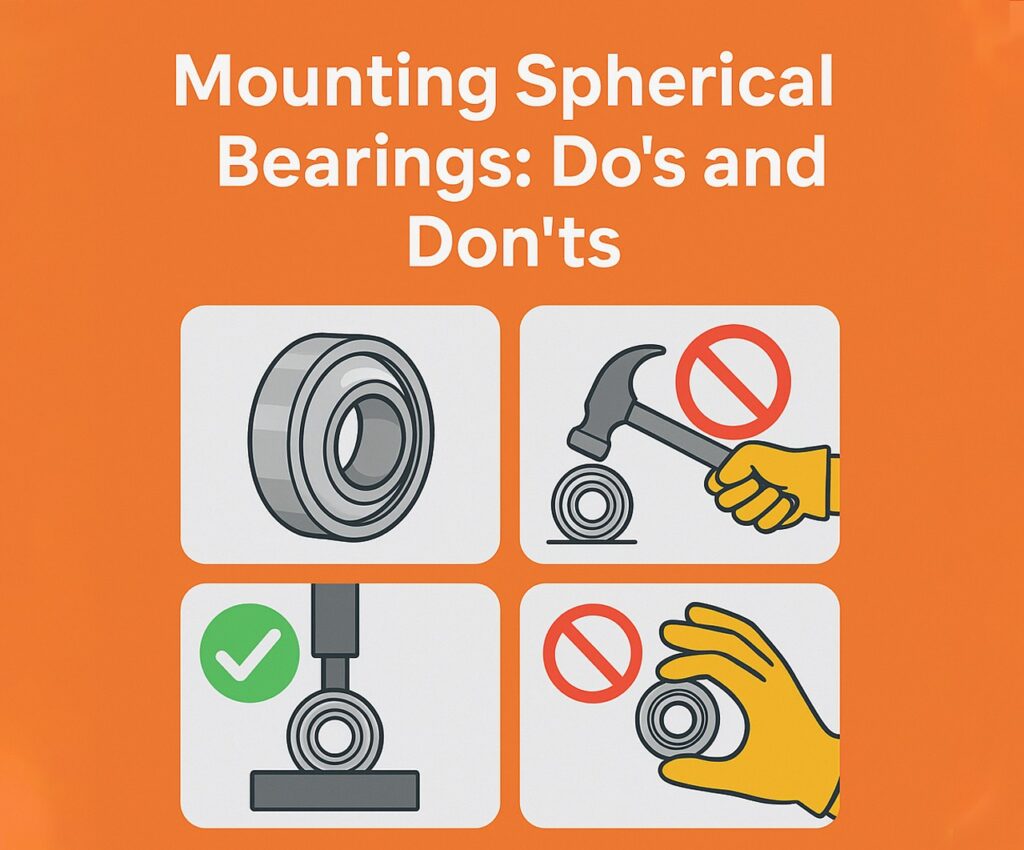

DON’T: Use Excessive Force

Never hammer or forcibly press a spherical bearing into place. The rolling elements and raceways are precision-machined to tight tolerances. Excessive force can:

- Dent the raceways

- Misalign the rollers

- Damage the PTFE or cage structure (if applicable)

Instead, use specialized mounting tools or heating methods when working with double row self aligning spherical roller bearing components.

DO: Align the Bearing and Shaft Properly

Because a bearing roller spherical can self-align, some installers assume that perfect alignment isn’t necessary. That’s false. The bearing compensates for small misalignments, not gross installation errors. Make sure:

- The shaft is centered in the housing

- The shaft shoulder and bearing face are parallel

- The bearing is seated evenly without gaps

Poor alignment causes edge loading, leading to wear and shortened lifespan.

DON’T: Skip the Instruction Manual

Mounting an axial spherical roller bearing isn’t always intuitive. Always refer to the manufacturer’s guide. Different brands may require:

- Specific torque values

- Directional orientation (particularly for axial bearings)

- Use of adapter sleeves or locknuts

Assuming you “know how it goes” can void warranties and lead to expensive downtime.

DO: Use Correct Lubrication

Spherical bearings, especially the double row self aligning spherical roller bearing, operate under high loads and varying speeds. Lubrication is critical. Use:

- High-load grease for static or oscillating loads

- Oil circulation for continuous high-speed applications

- Sealed-for-life options if maintenance access is limited

Pre-fill the bearing with the right amount—too much grease can cause overheating, while too little increases wear.

DON’T: Mix and Match Components

Stick to components from the same supplier or those specifically rated as compatible. Mixing brands or using aftermarket parts can introduce inconsistencies in:

- Inner ring taper

- Outer ring geometry

- Cage dimensions

These variations can compromise the performance of an axial spherical roller bearing under load.

DO: Use Heating Methods for Interference Fits

For tight fits, consider induction heaters to thermally expand the bearing’s inner ring. This ensures:

- Uniform expansion

- No contact stress during installation

- Better seating on the shaft

This is especially important for bearing roller spherical types in high-torque applications, where secure fit is non-negotiable.

DON’T: Over-Tighten Locknuts

When using adapter or withdrawal sleeves, over-tightening locknuts can damage threads or distort the bearing bore. Always:

- Follow torque guidelines

- Use calibrated tools

- Recheck torque after a short operational run-in

Over-torquing a double row self aligning spherical roller bearing may also cause inner ring fractures under load.

DO: Verify the Fit After Installation

After mounting, rotate the shaft by hand and feel for smoothness. Look for:

- Uniform resistance

- No binding or wobbling

- Clean rotation without metal-on-metal noise

For axial spherical roller bearing systems, test under simulated axial load to ensure the bearing is seated and operating as designed.

DON’T: Neglect Post-Installation Checks

Even a perfect installation needs follow-up. Run checks after 100 hours of operation to:

- Re-grease if required

- Inspect for unusual heat or vibration

- Re-check locking mechanisms or fasteners

In systems using a bearing roller spherical, misalignment or uneven torque loads may not show up immediately. Periodic inspections help catch issues early.

Smart Mounting Tools to Consider

Use the right tools to streamline mounting:

- Hydraulic nuts and pumps for large bore bearings

- Induction heaters with temperature control

- Alignment kits and dial indicators

- Vibration analyzers for post-install diagnostics

Using professional tools not only extends the life of your double row self aligning spherical roller bearing but also reduces installation time and improves safety.

Industry Use Cases

Wind Turbines Mounting precision matters in rotor hubs. Misalignment of a bearing roller spherical here can lead to catastrophic downtime.

Mining Equipment Large, slow-speed shafts rely on properly mounted double row self aligning spherical roller bearing units to prevent excessive shaft deflection and structural fatigue.

Steel Mills High temperatures and dynamic loads make proper lubrication and mounting crucial for axial spherical roller bearing applications.

Final Thoughts

Mounting a spherical bearing is more than just fitting a part—it’s a high-stakes operation that determines the success and reliability of your machine. Whether it’s an axial spherical roller bearing, a bearing roller spherical, or a double row self aligning spherical roller bearing, getting the mounting process right is the first step to maximizing performance.

Follow these do’s and don’ts, trust your tools, and lean on manufacturer guidelines to ensure every installation delivers the results your system demands. Proper mounting isn’t just smart—it’s essential.