When precision, flexibility, and durability are key in rotating equipment, few components are as versatile as the self-aligning ball bearing. Whether you’re working on an industrial drive shaft, conveyor system, or agricultural equipment, understanding the cage material can be the difference between long-term reliability and premature failure. After all, a 2220 self aligning ball bearing has a critical design that allows for shaft misalignment and reduced friction, thanks in part to the cage that keeps the balls evenly spaced. In specialized applications, the choice between steel, brass, or nylon cages becomes essential—especially when dealing with an external self aligning ball bearing or high-load conditions. If you’re in search of the best material for your self aligning ball bearing application, this guide offers a side-by-side comparison packed with practical insights. Know More

What Are Self-Aligning Ball Bearings?

Self aligning ball bearings are unique among rolling-element bearings. Their inner ring has two rows of balls and a common spherical outer ring raceway. This geometry allows them to accommodate angular misalignment without compromising performance.

A 2220 self aligning ball bearing has a specific designation that indicates size and capacity. The ‘2220’ refers to:

- ‘22’: Bearing series

- ‘20’: Bore size code (100mm bore)

This type of bearing is ideal in applications where mounting errors or shaft deflection could otherwise cause premature wear or noise. Whether used internally or as an external self aligning ball bearing, the cage is vital for proper ball separation and smooth operation.

The Role of Cages in Self-Aligning Ball Bearings

The cage, or retainer, is the component that maintains equal spacing between rolling elements. It prevents contact between the balls and helps to evenly distribute the load and reduce friction.

The choice of cage material significantly impacts:

- Load capacity

- Friction and heat generation

- Resistance to vibration

- Operating speed

- Chemical compatibility

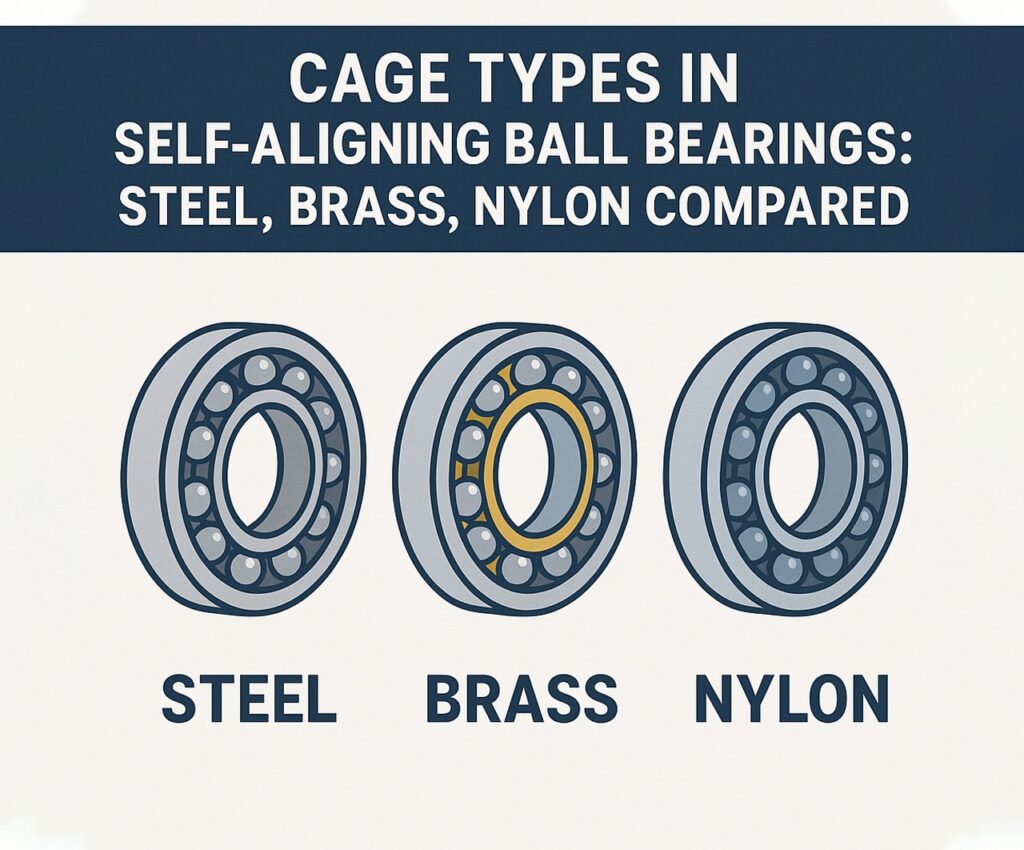

With that in mind, let’s compare the three most common cage types: steel, brass, and nylon.

Steel Cages: Durable and Rigid

Overview

Steel cages are made of pressed or machined carbon or stainless steel. They’re known for their strength and thermal resistance.

Advantages

- High rigidity and strength under heavy loads

- Excellent temperature tolerance (up to 300°C)

- Resistant to deformation

- Suitable for high-speed applications

Drawbacks

- Higher weight compared to brass or nylon

- Noisy in vibration-prone environments

- Prone to corrosion unless stainless steel is used

Best For:

- Industrial motors

- Mining equipment

- High-speed conveyors

- Applications with high static or dynamic loads

Steel is often the go-to in extreme conditions where bearing failure is not an option. In fact, many designs of a 2220 self aligning ball bearing has a steel cage by default for rugged reliability.

Brass Cages: Balanced and Long-Lasting

Overview

Machined brass cages are used where impact loads, vibration, or lubrication issues might arise. Brass is softer than steel but more stable than nylon.

Advantages

- Corrosion-resistant in lubricated environments

- Good damping characteristics—reduces noise

- Excellent dimensional stability

- High resistance to wear and seizure

Drawbacks

- Heavier than nylon

- More expensive to manufacture

- Slightly lower maximum speed limits compared to steel

Best For:

- Gearboxes

- Pumps

- Paper processing equipment

- Low-noise or vibration-sensitive environments

Brass strikes a solid middle ground. In many external self aligning ball bearing systems exposed to environmental variation, brass offers superior lifespan.

Nylon Cages: Lightweight and Cost-Effective

Overview

Nylon (polyamide) cages are injection-molded and known for their low weight and smooth operation. They’re popular in compact, low-noise, or cost-sensitive designs.

Advantages

- Low friction and noise generation

- Lightweight—ideal for reducing overall machine mass

- Cost-effective

- Self-lubricating in many cases

Drawbacks

- Lower temperature resistance (up to ~120°C)

- Degrades in presence of certain lubricants or moisture

- Less durable under heavy or shock loading

Best For:

- Small motors

- HVAC systems

- Home appliances

- Light-duty agricultural tools

In self aligning ball bearing systems used in consumer goods, nylon cages help reduce weight and simplify maintenance. But their limitations in high-load and high-temperature situations make them less suited for industrial machinery.

How Cage Type Affects Bearing Performance

1. Operating Speed

- Steel and brass support higher RPMs.

- Nylon is good for medium speeds but offers quieter operation.

2. Load Handling

- Steel performs best under high dynamic loads.

- Brass provides balance and stability.

- Nylon should only be used for moderate or light loading.

3. Corrosion Resistance

- Brass is corrosion-resistant in oil-based lubrication.

- Nylon resists light moisture but degrades in water-based or aggressive fluids.

- Steel must be stainless or coated for corrosion resistance.

4. Temperature Limits

- Steel: up to 300°C

- Brass: up to 250°C

- Nylon: up to 120°C (and degrades at lower temps if stressed)

5. Noise and Vibration

- Nylon is the quietest.

- Brass has damping properties.

- Steel is prone to higher acoustic output under load.

Each variation of a 2220 self aligning ball bearing has a role depending on the environmental and operational specifics.

External Self Aligning Ball Bearings: Cage Demands in Harsh Environments

An external self aligning ball bearing is often exposed to dirt, moisture, chemicals, or fluctuating temperatures. Choosing the right cage is crucial here:

- Steel for maximum strength in high-impact areas

- Brass for good compromise in agricultural or marine conditions

- Nylon only if properly shielded and temperature-controlled

In outdoor or remote environments, maintenance intervals may be long, making durable cage materials more critical.

Maintenance and Lubrication Tips by Cage Type

Steel Cages

- Grease or oil lubrication required

- Inspect for corrosion during scheduled maintenance

- Ideal for long-duration industrial systems

Brass Cages

- Tolerates inconsistent lubrication

- Best when used with oil bath systems

- Clean buildup from surface occasionally

Nylon Cages

- Use compatible greases (avoid EP additives)

- Avoid high-humidity or chemically reactive environments

- Replace if discoloration or brittleness appears

Future Developments in Cage Materials

The bearing industry is always evolving. New materials and coatings are being developed for cage applications:

- Hybrid cages combining brass and polymer

- Carbon-fiber-reinforced cages for aerospace

- PTFE-coated brass for ultra-low friction

- Graphene-infused nylon for higher temperature resistance

These innovations aim to overcome the limitations of traditional materials, especially in challenging external self aligning ball bearing environments.

Summary Table: Steel vs. Brass vs. Nylon Cages

| Property | Steel Cage | Brass Cage | Nylon Cage |

| Load Capacity | High | Medium-High | Low-Medium |

| Max Temperature | 300°C | 250°C | 120°C |

| Noise/Vibration | Moderate | Low | Very Low |

| Corrosion Resistance | Low | Moderate | Moderate |

| Lubrication Tolerance | Medium | High | Low |

| Cost | Low | Medium | Lowest |

| Maintenance Interval | Long | Moderate | Short |

| Ideal For | Industrial Loads | Balanced Systems | Light-duty Systems |

Final Thoughts

From high-speed industrial motors to quiet domestic fans, self aligning ball bearings deliver unmatched flexibility. But the hidden hero behind this performance is the cage. Whether a 2220 self aligning ball bearing has a steel cage for strength, a brass cage for balance, or a nylon cage for noise reduction, the choice has significant implications for performance, longevity, and cost.

In particularly tough environments—like with an external self aligning ball bearing exposed to water, dust, or chemicals—the cage must go beyond function and become a line of defense. By understanding the benefits and trade-offs of each cage material, engineers and technicians can optimize bearing selection for any application.

Remember, the right cage isn’t just about performance—it’s about reliability, efficiency, and total lifecycle value. Choose wisely, and your self aligning ball bearings will keep systems turning smoothly for years to come.