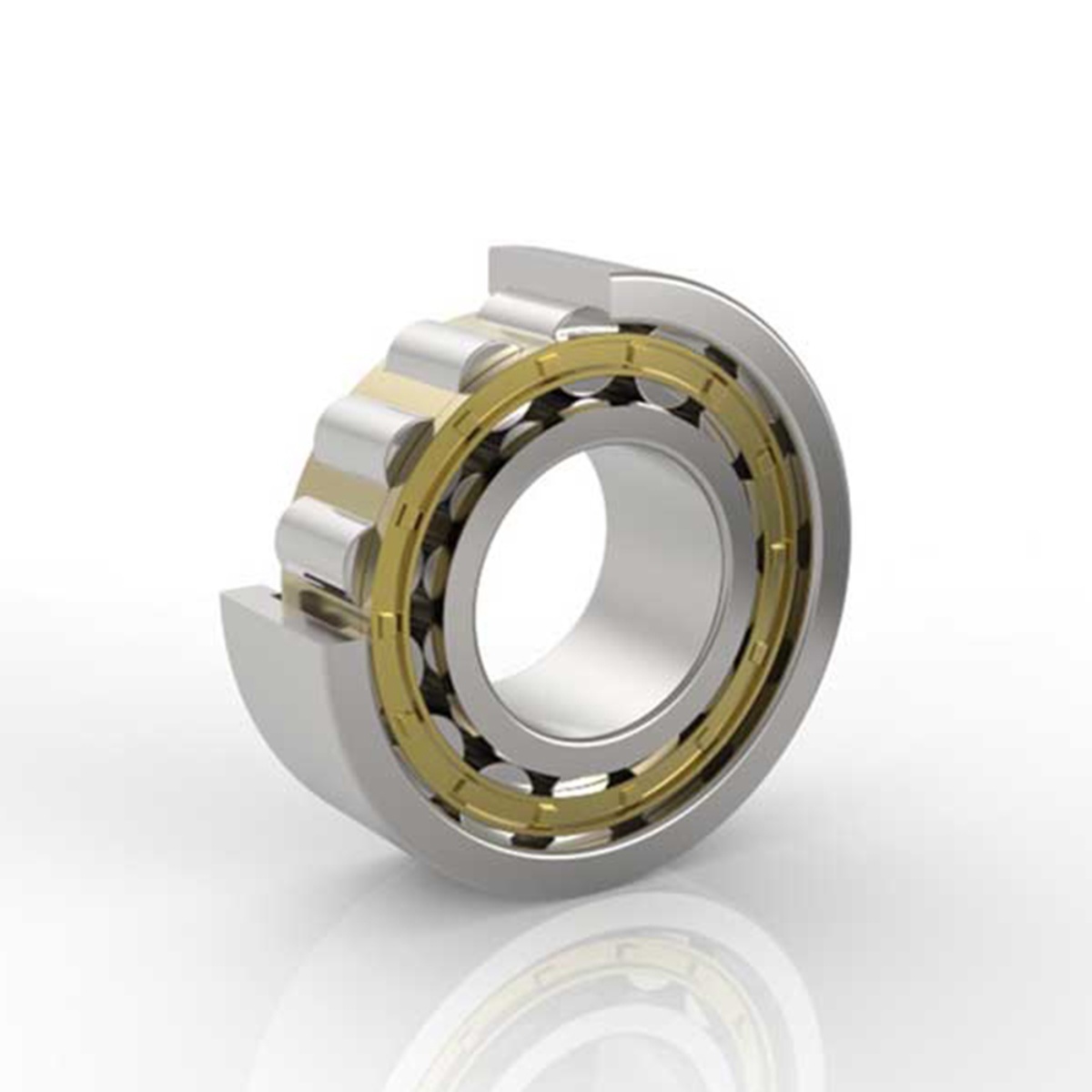

Engineered for Industrial Endurance | High Quality Cylindrical P6 Steel Roller Bearing For Machine

Designed to meet the rigorous demands of industrial-grade machinery, the High Quality Cylindrical P6 Steel Roller Bearing For Machine delivers enhanced radial load performance and long-term operational reliability. Manufactured with precision P6 tolerances and constructed using robust Chrome Steel GCR15, this cylindrical roller bearing excels in applications requiring high-speed rotation, consistent alignment, and reduced friction. Its steel cage promotes optimal roller guidance and even load distribution—making it a dependable component in machine tools, conveyors, compressors, and automated systems.

Whether for general machinery or advanced mechanical assemblies, this bearing maintains dimensional accuracy under stress, resisting deformation and ensuring smooth functionality over extended use cycles. Built for engineers, OEMs, and maintenance professionals alike, it stands as a dependable solution for delivering machine efficiency with minimal downtime.

Technical Specifications

| Attribute | Details |

|---|---|

| Product Name | High Quality Cylindrical P6 Steel Roller Bearing For Machine |

| Material | Chrome Steel GCr15 |

| Precision Rating | P0, P6, P5, P4, P2 |

| Seals Type | Open |

| Number of Row | Single row |

| Structure | Cylindrical |

| Type | Roller |

| Application | Machinery |

| Applicable Industries | Manufacturing Plant, Machinery Repair Shops, Food & Beverage Factory, Retail, Construction Works, Energy & Mining |

| Inner Diameter (ID) | 15 – 260 mm |

| Outer Diameter (OD) | 35 – 540 mm |

| Width | According to the size |

| Load Capacity | High radial load capacity |

| Speed Rating | High-speed performance (based on precision class) |

| Lubrication | Oil or Grease |

| Cage Material | Steel / Brass / Nylon |

| Temperature Range | -40°C to +150°C |

| Noise Level | Low noise, suitable for precision equipment |

Why Choose High Quality Cylindrical P6 Steel Roller Bearing For Machine?

🔹 Precision-machined P6 class cylindrical bearing for tight tolerance control

🔹 Engineered with high-purity Chrome Steel GCR15 for maximum hardness and wear resistance

🔹 Suitable for continuous radial load and limited axial load applications

🔹 Steel cage construction for enhanced thermal and structural stability

🔹 Grease-lubricated for prolonged service intervals

🔹 Offers excellent shock-load resistance and high-speed capability

🔹 Supports industrial automation, processing plants, and heavy-duty applications

🔹 Built for high-load industrial machinery with rotational consistency

🔹 Low noise and vibration for smoother operational output

🔹 Long-life service with options in C0, C2, and C3 clearances

Maintenance Tips for Longevity

To ensure the High Quality Cylindrical P6 Steel Roller Bearing For Machine performs at its peak over an extended lifespan, consistent and proper maintenance is essential. Industrial environments often expose bearings to dust, moisture, vibration, and high temperatures—factors that can accelerate wear if not addressed proactively. Adopting a regular servicing routine not only preserves bearing integrity but also minimizes downtime and improves overall machine efficiency. Below are essential maintenance practices to maximize bearing reliability and durability:

🔹 Clean bearing units with non-corrosive industrial solvent at regular intervals

🔹 Re-lubricate using high-grade grease after scheduled inspections

🔹 Avoid contamination by keeping bearings sealed and dust-free

🔹 Ensure precision fitting with proper mounting tools and torque

🔹 Store in a moisture-controlled environment to prevent internal corrosion

Order Now – High Quality Cylindrical P6 Steel Roller Bearing For Machine

Upgrade your industrial systems with a component engineered to outperform. The High Quality Cylindrical P6 Steel Roller Bearing For Machine delivers an ideal mix of performance, stability, and affordability. Whether used in a manufacturing plant or precision-engineering shop, it guarantees efficiency, accuracy, and cost-effectiveness with every rotation.

Reviews

There are no reviews yet.