In high-performance mechanical systems, securing components precisely and reliably is non-negotiable. This is especially true in assemblies where bearings must remain stable under load, speed, and vibration. That’s where retaining rings, including both the internal retaining ring and external retaining ring, come into play. These deceptively simple components are the unsung heroes of rotational systems, ensuring that bearings stay in position without adding unnecessary bulk or complexity.

If you’ve ever wondered how a tiny steel clip can keep a high-speed bearing from walking out of its housing, this article will guide you through the engineering behind retaining rings, their types, uses, and why they’re a smart design choice in modern assemblies. Know More

What Are Retaining Rings?

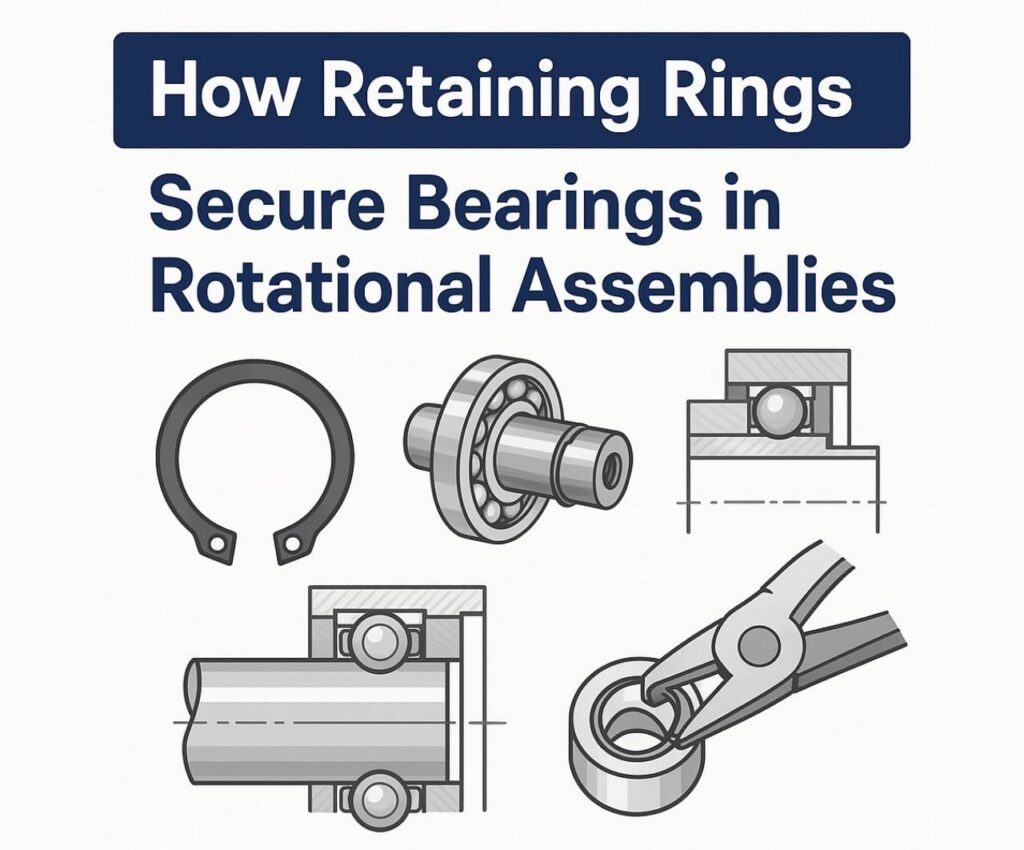

Retaining rings, also known as snap rings or circlips, are circular fasteners designed to fit into a groove on a shaft or inside a bore. They hold components like bearings, gears, or pulleys in place axially. Instead of relying on nuts, bolts, or other bulky fasteners, retaining rings provide a lightweight and efficient solution for axial location control.

Depending on where they’re mounted, retaining rings fall into two categories:

- Internal retaining ring: Fits into a groove inside a cylindrical bore

- External retaining ring: Snaps into a groove on the outside of a shaft

Both types are designed to resist axial motion and are commonly used in applications ranging from automotive engines to consumer electronics.

Why Bearings Need Retaining Rings

Bearings facilitate smooth motion in assemblies by reducing friction between moving parts. But without proper axial constraint, even the most advanced bearing can shift or misalign, leading to vibration, noise, and premature failure.

Here’s how retaining rings help:

- Prevent axial movement: They lock the bearing in place against a shoulder or groove.

- Distribute load: Proper ring placement helps distribute axial loads evenly.

- Simplify assembly: They reduce the need for complex housing designs or additional components.

- Allow for disassembly: Rings can be removed and reused, making maintenance easier.

Types of Retaining Rings for Bearings

Let’s take a closer look at the different types and where they excel.

1. Internal Retaining Ring

The internal retaining ring is inserted into a groove on the inside diameter of a bore. It prevents components like bearings or bushings from moving outward.

Applications:

- Gearboxes

- Electric motors

- Hydraulic pumps

Advantages:

- Compact design

- High load resistance

- Easy to install with pliers or automated tools

Common materials: Carbon steel, stainless steel, beryllium copper for corrosion resistance

2. External Retaining Ring

The external retaining ring fits onto the outside of a shaft and holds components from sliding inward.

Applications:

- Automotive transmissions

- Bicycle crank assemblies

- Aerospace actuators

Advantages:

- Excellent for rotary shafts

- Quick installation

- Secure retention without threading or adhesives

Like their internal counterparts, external retaining rings come in various materials and finishes, including black oxide or zinc plating for added protection.

Innovative Designs and Profiles

Standard round-section rings aren’t the only game in town. Today’s engineering demands have given rise to specialized profiles:

- Spiral rings: Coiled from flat wire, offering 360° contact

- Constant section rings: Uniform thickness for balanced load distribution

- Self-locking rings: Feature notches or projections that engage with the groove

These variants provide design flexibility, allowing engineers to fine-tune performance while maintaining compactness.

Engineering Considerations When Using Retaining Rings

When selecting a retaining ring, it’s not just about inside or outside mounting. Several key factors influence performance:

- Groove geometry: Proper groove depth and width are critical for retention strength.

- Material strength: Choose a ring material compatible with the operating environment (heat, corrosion, magnetic fields).

- Speed and load: High-speed assemblies require rings with minimal imbalance.

- Ease of installation: For mass production, choose rings that suit automated placement tools.

- Deflection: Rings should accommodate shaft or bore expansion without permanent deformation.

Real-World Examples

Let’s see how retaining rings perform in practical applications:

Case Study 1: Electric Motor Assembly

A compact brushless DC motor uses an internal retaining ring to hold the bearing in the housing. The ring resists axial thrust caused by shaft acceleration and sudden stops. With proper groove design, the ring supports thousands of hours of operation without shifting or fatigue.

Case Study 2: Automotive Gearbox Shaft

A high-torque transmission shaft incorporates an external retaining ring to secure a thrust washer and bearing. The ring’s hardened steel composition and precise fit withstands extreme rotational speeds and pressure without backing out or distorting.

Case Study 3: Wind Turbine Bearings

In harsh, wind-swept environments, a self-locking internal retaining ring is used to retain bearings in the yaw motor. These rings offer resistance to vibration and shock loads and are made from stainless steel with anti-corrosion coatings.

Installation and Removal Best Practices

Proper installation ensures performance and longevity. Here are some key steps:

- Use the right tools: Use pliers or automated ring applicators; avoid prying with screwdrivers.

- Check groove integrity: A poorly machined groove compromises retention.

- Avoid overstretching: Over-expanding a ring reduces its spring tension.

- Inspect fit: After installation, verify that the ring sits fully in the groove with no distortion.

For removal, use precision ring pliers to minimize deformation and prevent damage to nearby components.

Retaining Rings vs. Other Fasteners

Why use retaining rings instead of nuts, bolts, or adhesives?

- Lighter and smaller: Ideal for compact assemblies

- Lower cost: Minimal machining required

- Reusability: Easily removed without damage

- No threading required: Simplifies shaft design

That said, retaining rings aren’t for every application. Extremely high axial loads or shock environments might require additional retention methods such as shoulder bolts or keyways.

Trends in Retaining Ring Manufacturing

As automation and miniaturization grow, so does the demand for smarter, smaller, and more reliable retaining rings.

- Precision stamping techniques now produce rings with tighter tolerances.

- Smart materials like shape-memory alloys are being explored for rings that adjust under thermal loads.

- Additive manufacturing allows for custom profiles and one-off prototypes.

In industries like robotics, medical devices, and aerospace, such innovations lead to lighter, more reliable systems.

Sustainability and Lifecycle Considerations

Sustainability isn’t often associated with fasteners, but retaining rings have advantages here too:

- Minimal raw material usage

- High recyclability (especially in stainless or carbon steel)

- Extended lifecycle due to reusability

Unlike adhesives or welds, retaining rings can be removed and reused without generating waste, aligning with circular economy principles.

Final Thoughts

The simple retaining ring, whether it’s an internal retaining ring snug in a motor housing or an external retaining ring gripping a shaft under load, plays a vital role in bearing retention and overall system integrity. In rotational assemblies, where failure isn’t an option, these rings provide a reliable, cost-effective solution for engineers and manufacturers alike.

By understanding the distinctions between types, materials, and applications, you can make smarter choices in your next design project. As mechanical systems evolve and performance expectations increase, retaining rings will continue to prove that the smallest components often carry the biggest responsibilities. Know More