When it comes to machinery performance and longevity, few components play a more critical role than bearings. Whether you’re dealing with high-speed industrial motors or consumer appliances, the choice between sealed deep groove ball bearings, a double row deep groove ball bearing, and a shielded deep groove ball bearing can significantly impact efficiency, maintenance cycles, and overall durability. In this guide, we’ll explore what sets shielded and sealed bearings apart, how they perform in real-world applications, and when you should choose one over the other. Know More

Understanding the Basics

At their core, deep groove ball bearings are designed to support both radial and axial loads. Their versatility and simplicity make them the most widely used type of rolling bearing. But not all deep groove bearings are the same.

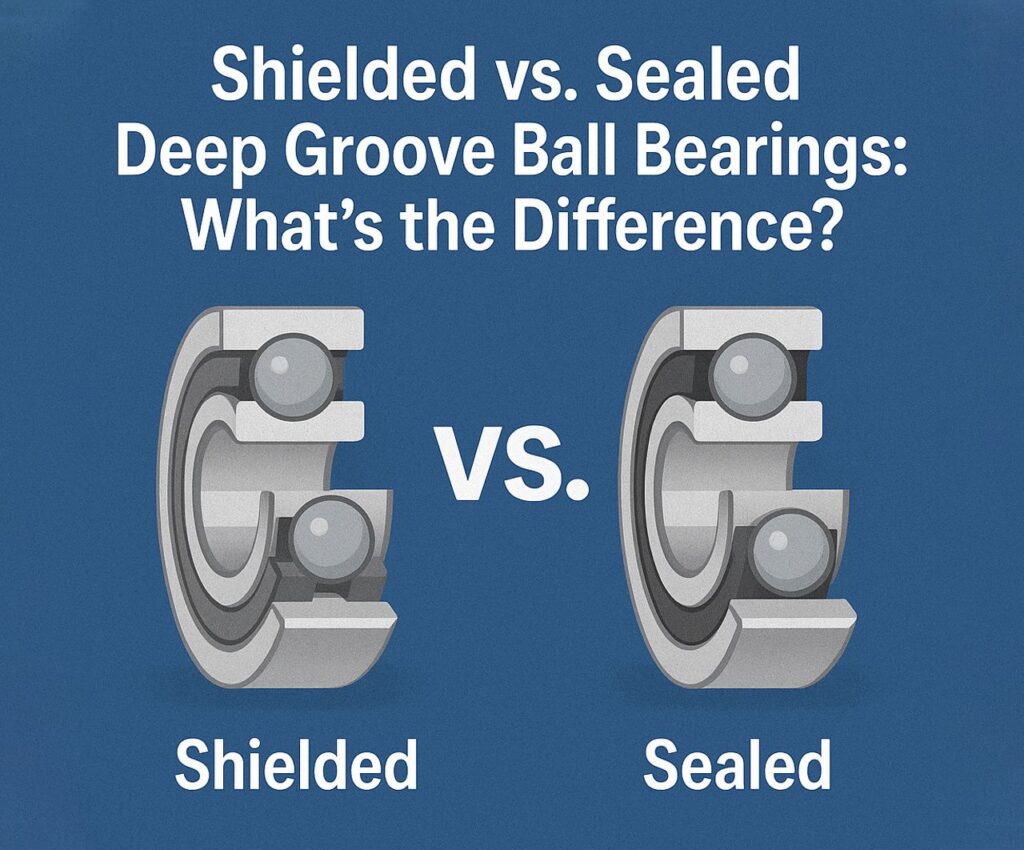

- A sealed deep groove ball bearing includes rubber or synthetic seals that prevent contaminants from entering and keep lubricants locked in.

- A shielded deep groove ball bearing features metal shields that offer partial protection against larger particles and light exposure to moisture.

- A double row deep groove ball bearing has two rows of balls instead of one, providing enhanced load capacity and radial stiffness.

These differences in design lead to varied applications, life spans, and maintenance requirements.

Shielded Deep Groove Ball Bearings: Built for Moderate Protection

A shielded deep groove ball bearing typically uses steel shields (often labeled as “ZZ” in bearing nomenclature) that are mounted in the outer ring and extend close to the inner ring. These shields create a narrow gap that helps minimize entry of dust or debris.

Pros:

- Less friction compared to sealed types

- Suitable for high-speed environments

- Lower operating temperatures

- Minimal torque resistance

Cons:

- Not waterproof or dust-tight

- Requires external lubrication maintenance

Shielded bearings are ideal for environments where the risk of contamination is low and high rotational speed is a priority. They’re commonly found in electric motors, HVAC fans, and pumps.

Sealed Deep Groove Ball Bearings: Maximum Contamination Control

A sealed deep groove ball bearing is designed with synthetic rubber seals (marked “2RS” or “RS”) that make contact with the inner ring. These seals create a more secure barrier, ideal for dirty or wet environments.

Pros:

- Exceptional sealing against dust, dirt, and moisture

- Factory-lubricated for life

- Reduces maintenance intervals

- Enhances bearing life in hostile conditions

Cons:

- Slightly higher friction and torque

- Not suitable for extreme high-speed applications

- Traps heat more than shielded bearings

Sealed bearings are used in agricultural machinery, washing machines, and industrial conveyors where reliability in dirty environments is critical.

The Role of Double Row Deep Groove Ball Bearings

A double row deep groove ball bearing takes the performance of single row bearings to the next level. With two rows of balls, it can support significantly higher radial loads. This configuration also improves rigidity and reduces bearing deflection under heavy loads.

Key Characteristics:

- Available in both sealed deep groove ball bearings and shielded deep groove ball bearing formats

- Excellent for radial-heavy applications like gearboxes, winches, and elevator motors

- Slightly wider and heavier than single row versions

Real-World Applications Comparison

Let’s look at a few practical examples:

Industrial Fans:

These demand high speed and operate in relatively clean conditions. A shielded deep groove ball bearing works best here due to its lower friction and heat resistance.

Food Processing Equipment:

This industry requires stringent hygiene and is prone to moisture and contaminants. A sealed deep groove ball bearing ensures better sealing and consistent lubrication, minimizing downtime and risk of contamination.

Mining Equipment:

Heavy radial loads and exposure to dirt make the double row deep groove ball bearing the optimal choice, especially in its sealed variant.

Choosing the Right Bearing for Your Application

When deciding between a sealed deep groove ball bearing, shielded deep groove ball bearing, or a double row deep groove ball bearing, ask these questions:

- What’s the contamination risk in your environment?

- What is the required speed of rotation?

- Will the bearing face heavy or moderate loads?

- How often can maintenance be performed?

If contamination is minimal and speed is critical, go for the shielded deep groove ball bearing. For maintenance-free, all-weather performance, choose the sealed deep groove ball bearing. And when your system demands strength and capacity, the double row deep groove ball bearing will deliver.

Maintenance and Lifespan Insights

The type of bearing you choose affects your maintenance routines:

- Shielded bearings need periodic lubrication, usually through the machinery’s lubrication system.

- Sealed bearings are pre-lubricated and generally maintenance-free.

- Double row bearings, depending on their sealing, may need regular inspection but typically have a longer life span due to load-sharing.

In dusty environments, unsealed or unshielded bearings fail quickly. Investing in a sealed deep groove ball bearing significantly reduces this risk.

Cost Considerations

- Shielded deep groove ball bearing: Usually more affordable, ideal for general-purpose applications.

- Sealed deep groove ball bearings: Slightly more expensive due to seal integration but save on long-term maintenance.

- Double row deep groove ball bearing: Highest upfront cost, justified by superior load handling and durability.

When budgeting for bearings, consider the total cost of ownership, not just the price tag. Replacing a failed bearing often involves labor, downtime, and equipment wear that far exceeds the cost of the part.

Innovations and Industry Trends

Manufacturers are constantly improving:

- Low-friction seals for sealed deep groove ball bearings

- Heat-resistant shield materials for high-speed applications

- Hybrid ceramic balls in double row deep groove ball bearing types for added strength

There’s also a push toward smart bearings with integrated sensors to monitor load, temperature, and vibration in real time.

Final Thoughts

Choosing the right bearing isn’t just a technical decision—it’s a strategic one. Whether your priority is contamination control, high-speed performance, or heavy load support, there’s a bearing configuration to match.

The sealed deep groove ball bearing offers superior protection for rough environments. The shielded deep groove ball bearing provides high-speed performance in clean conditions. And for those needing enhanced strength, the double row deep groove ball bearing steps up with extra load support.

As industries across the globe modernize and adopt smarter maintenance strategies, knowing the differences between these bearing types is more important than ever. The right choice leads to longer life, lower costs, and better machine reliability—something every engineer and plant manager can get behind.