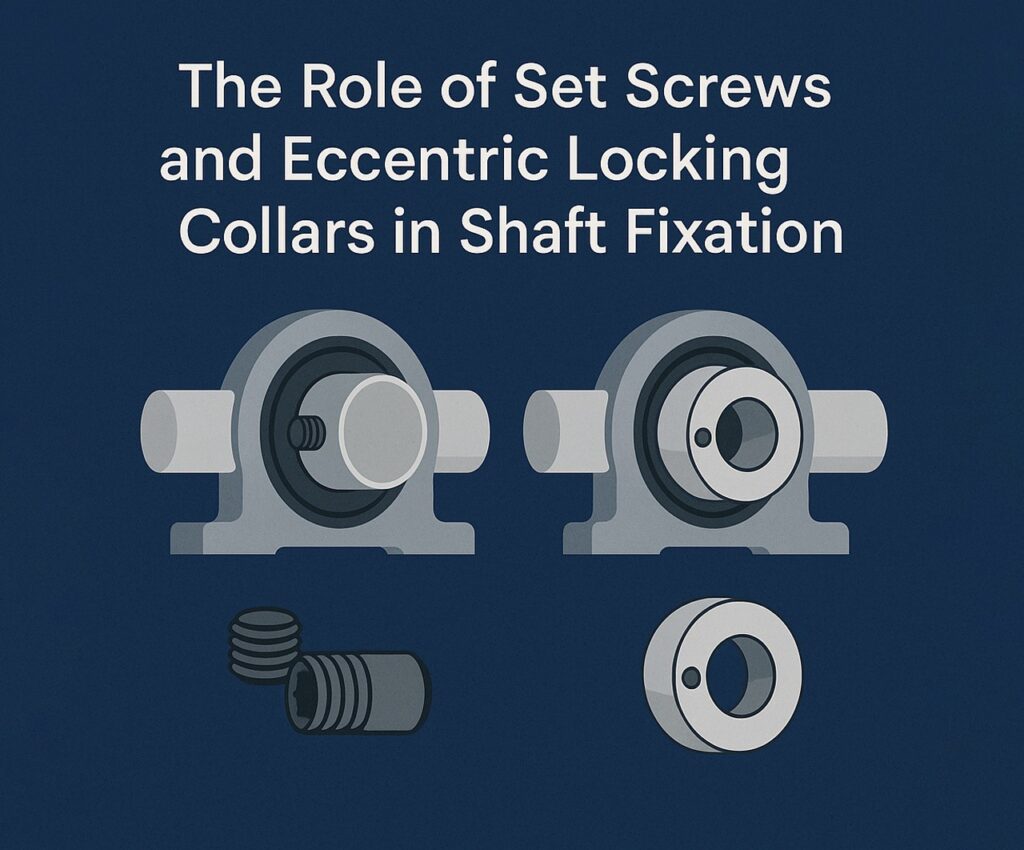

In machinery that relies on rotational motion, secure shaft fixation is vital to ensure performance and prevent mechanical failure. Whether you’re using a pillow block bearing insert for agricultural equipment, selecting a 1 insert bearing for light-duty applications, or upgrading a ball insert bearing in a conveyor system, choosing the right locking method—set screws or eccentric locking collars—can determine the success and longevity of your equipment. These simple components play a critical role in how well the bearing holds onto the shaft under dynamic conditions.

This article explores the strengths, limitations, and best applications for set screws and eccentric locking collars and how they interact with different types of insert bearings. Know More

Understanding Shaft Fixation in Insert Bearings

Insert bearings, such as a ball insert bearing or a 1 insert bearing, are self-contained bearing units designed to be mounted easily onto a shaft. They’re commonly used in pillow block housings, flange mounts, and other configurations.

A pillow block bearing insert is a popular option due to its adaptability and ease of installation. But to function correctly, the insert must stay fixed to the shaft under load, rotation, and vibration. That’s where set screws and eccentric locking collars come into play.

What Are Set Screws?

Set screws are small threaded fasteners used to press against the shaft inside the bearing’s inner ring. Most ball insert bearing units feature two set screws placed 120° apart for balanced pressure.

Advantages of Set Screws:

- Simple and quick to install

- No special tools required

- Effective for moderate-speed applications

Limitations:

- Can mar the shaft surface

- May loosen under heavy vibration

- Less holding power compared to eccentric collars in shock-prone environments

Set screw locking is ideal for:

- Light-duty conveyors

- HVAC fans

- Agricultural sprayers using a standard 1 insert bearing

What Are Eccentric Locking Collars?

Eccentric locking collars provide a more secure fixation by wrapping around the shaft with an off-center cam design. As the collar rotates, it tightens against the shaft. Once aligned, a set screw in the collar locks it into place.

Benefits of Eccentric Collars:

- Stronger holding force than traditional set screws

- Better for high-vibration applications

- Doesn’t damage shaft like direct screw contact

Considerations:

- Slightly more complex installation

- Requires collar alignment before tightening

Common uses:

- Grain elevators

- High-speed agricultural machinery

- Any pillow block bearing insert in a vibrating or shock-loaded system

Comparing Set Screws and Eccentric Collars

| Feature | Set Screws | Eccentric Locking Collars |

| Installation Time | Faster | Slightly slower |

| Vibration Resistance | Moderate | High |

| Shaft Surface Impact | Can mar shaft | Minimal impact |

| Holding Strength | Good | Superior |

| Tools Needed | Allen wrench | Allen wrench + alignment |

How These Methods Affect Different Insert Bearings

1 Insert Bearing

Often used in small motors or compact systems, 1 insert bearing units benefit from set screws for quick installation and lower rotational demands. For higher speeds or external shock, eccentric collars offer better stability.

Ball Insert Bearing

These versatile bearings come in both locking styles. Choose set screws for systems with consistent load and minimal vibration. Opt for eccentric collars in unpredictable or high-impact operations.

Pillow Block Bearing Insert

Typically mounted in rugged environments, a pillow block bearing insert paired with an eccentric locking collar handles shaft expansion, misalignment, and shock much better than set screws.

Installation Tips for Set Screws

- Clean the Shaft: Dirt or oil reduces friction between shaft and screw.

- Align the Bearing: Make sure the shaft and housing are square before tightening.

- Torque Gradually: Tighten screws alternately and evenly to distribute pressure.

- Use Threadlocker: For high-vibration areas, consider medium-strength threadlocker to prevent loosening.

Installation Tips for Eccentric Locking Collars

- Slide Collar into Position: The collar should sit flush against the bearing’s shoulder.

- Rotate Collar by Hand: Spin it in the direction of shaft rotation to engage the eccentric cam.

- Tighten Set Screw: Once the collar locks in place, secure it with the set screw.

- Double-Check Alignment: The shaft should turn freely without wobble.

When to Use Which Fixation Method

Choose Set Screws When:

- Shaft is case-hardened and less prone to scoring

- System runs at moderate speed and load

- Frequent bearing replacement is expected

Choose Eccentric Collars When:

- Shaft is softer or precision-machined

- Environment has frequent shock or directional changes

- Vibration is a concern

For example, if you’re replacing a pillow block bearing insert in a vibrating feed conveyor, eccentric locking provides a longer-lasting fix.

Innovations in Locking Technology

Modern ball insert bearing designs may include:

- Dual set screws with optimized spacing

- Pre-lubricated collars for corrosion resistance

- Smart-lock systems that reduce human error during install

Some 1 insert bearing units even come with integrated locking features that blend set screw and cam actions for hybrid performance.

Maintenance and Inspection

Regardless of fixation method:

- Check torque values periodically

- Inspect for shaft wear or set screw loosening

- Replace damaged collars or screws immediately

Always monitor bearings for noise, heat, or misalignment—these are signs your locking system might be failing.

Final Thoughts

While set screws and eccentric locking collars may seem like minor details, they play a significant role in how reliably a pillow block bearing insert, 1 insert bearing, or ball insert bearing performs. Choosing the right fixation method based on application demands can prevent downtime, extend component life, and reduce maintenance costs.

Set screws offer simplicity and speed, while eccentric collars deliver superior grip and shock resistance. Knowing when and how to use each is a subtle but essential skill in mechanical design and maintenance.