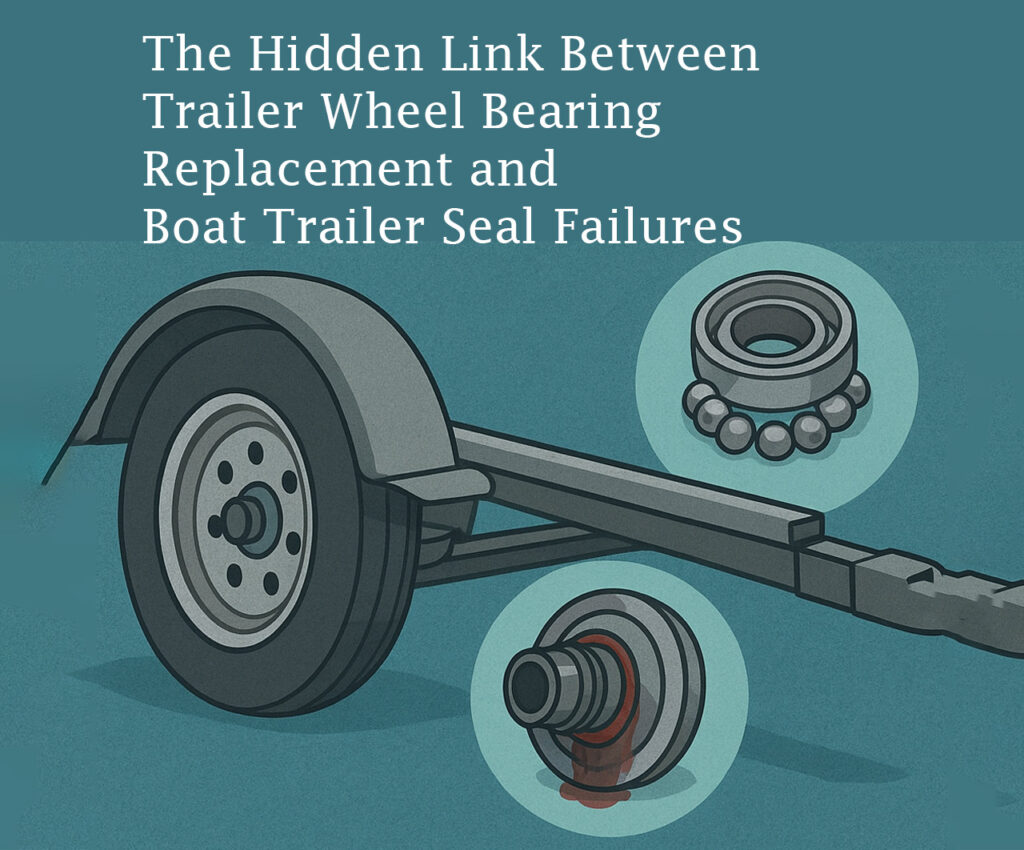

If you’ve ever dealt with changing bearings on trailer systems or performed a wheel bearing replacement trailer service, you know how crucial these components are for smooth towing. However, a hidden issue often escapes even seasoned trailer owners: the connection between boat trailer bearings and seals and premature seal failure. What if your bearings aren’t the only part at risk—and your seals are silently suffering the consequences?

In this article, we’ll uncover the overlooked relationship between trailer wheel bearings and seals, show you how improper maintenance or installation accelerates failure, and offer expert solutions to keep your trailer roadworthy and your boat secure. Know More

Understanding the Relationship Between Bearings and Seals

To appreciate the hidden link, you need to understand the mechanics of a wheel bearing replacement trailer setup. Bearings are designed to reduce friction between the trailer wheel and axle spindle, allowing smooth wheel rotation. Seals, on the other hand, protect those bearings from external contaminants like dirt, water, and road debris while keeping the grease inside.

When you’re changing bearings on trailer, the seals are your first and last line of defense. But here’s the issue—installing new bearings without checking or replacing the seals can compromise the whole system. And worse, damaged seals can ruin even freshly installed boat trailer bearings and seals setups.

The Most Common Seal Failures in Boat Trailers

Boat trailers are uniquely vulnerable due to their exposure to water—especially saltwater. If you’re neglecting seals while replacing your bearings, you might experience:

1. Water Ingress

Every time your trailer goes underwater, the seals are tested. If they’re damaged or improperly installed during wheel bearing replacement trailer maintenance, water seeps in. This causes immediate rust, grease breakdown, and bearing wear.

2. Grease Leakage

Seals are meant to trap lubricant inside the hub. But worn or misaligned seals lead to grease splatter on the inside of your wheels. This is often visible after changing bearings on trailer assemblies but not checking the seating of the new seals.

3. Overheated Bearings

Poor sealing leads to grease contamination or loss, resulting in metal-on-metal contact. This generates extreme heat, leading to warped races and failed boat trailer bearings and seals.

Why Seal Failure Undermines Your Wheel Bearing Replacement

Even if you’ve installed top-tier bearings, overlooking the seals essentially dooms the new setup. Here’s why:

- Contaminated grease reduces bearing performance.

- Rust from water ingress can pit the bearing surface within days.

- Heat degradation can cause melted seals and charred grease, making future changing bearings on trailer work harder and more expensive.

Worse still, if you’ve had a seal failure but continue towing, you’re risking a complete wheel lock-up or hub disintegration on the road. That’s a costly and dangerous price to pay for neglecting a small component.

The Right Way to Perform a Wheel Bearing Replacement for Boat Trailers

If you’re planning a wheel bearing replacement trailer service, follow this step-by-step method to avoid compromising your seals:

Step 1: Disassemble and Clean

Start by removing the hub assembly and cleaning all old grease. This helps you inspect not just the bearings, but also the contact surfaces for the seal.

Step 2: Inspect the Seal and Replace It

Never reuse an old seal. Any time you’re changing bearings on trailer, always install new seals. Look for high-quality marine-grade seals made for boat trailer bearings and seals setups.

Step 3: Grease Bearings Properly

Use marine-grade, water-resistant bearing grease and fully pack the bearings before inserting them. Improper greasing is one of the main contributors to premature seal failure.

Step 4: Properly Seat the Seal

Use a seal driver or a flat surface to press the seal evenly into the hub. A cocked or partially inserted seal is as bad as a broken one.

Step 5: Torque Correctly

Reassemble the hub and use a torque wrench to ensure the nut is neither too loose nor over-tightened. Excess pressure can deform the seal, leading to leaks.

Signs Your Boat Trailer Seals Have Already Failed

If you’ve recently done a wheel bearing replacement trailer job and are seeing any of the following symptoms, it’s likely your seals are compromised:

- Visible grease leaking from the backside of the hub

- Water-logged or milky grease (a sign of water contamination)

- Rumbling noise while towing

- Excessive heat from the hub when touched after a short drive

In such cases, don’t just consider changing bearings on trailer again—replace the seals immediately.

Choosing the Right Bearings and Seals for Marine Trailers

Not all boat trailer bearings and seals are created equal. Here are some expert tips for choosing the best components for marine use:

- Material matters: Opt for stainless steel or galvanized options for better corrosion resistance.

- Check compatibility: Match the bearing and seal sizes with your spindle. A mismatch can ruin the hub and cause failure on the road.

- Use double-lip seals: These provide superior water and grease retention compared to single-lip models.

- Choose OEM-certified components: For best results, always buy from trusted OEM suppliers to ensure longevity and performance.

How Improper Seal Maintenance Can Destroy New Bearings

One of the most overlooked causes of bearing damage is user error during changing bearings on trailer procedures. Let’s examine a few of the most damaging mistakes:

1. Over-packing Grease

Too much grease creates internal pressure, forcing it past the seal and leading to early failure.

2. Wrong Seal Size

Even a minor size mismatch causes spinning or wobbling during wheel motion, quickly destroying both seals and bearings.

3. Not Cleaning the Hub Before Seal Installation

Debris or old seal remnants create an uneven surface, preventing proper seating. This leads to a loose fit and early leakage—rendering your wheel bearing replacement trailer effort useless.

Expert Solution: Treat Bearings and Seals as One System

The golden rule for maintaining your trailer? Treat boat trailer bearings and seals as an inseparable duo. They must be serviced, inspected, and replaced together.

Every time you’re changing bearings on trailer, ask yourself:

- Are my seals in good condition?

- Do I have the right tools to seat them properly?

- Am I using marine-grade grease and components?

If the answer to any of those is “no,” you risk shortening the lifespan of your entire hub system.

Preventive Maintenance for Longer-Lasting Boat Trailer Bearings and Seals

If you want to extend the life of your boat trailer bearings and seals, follow these best practices:

- Flush after every use: Especially after saltwater trips.

- Inspect every 6 months: Check for play in the wheel, noise, or leaking grease.

- Keep a spare kit: Carry extra seals and bearings when traveling long distances.

- Avoid DIY shortcuts: Improper installation is the #1 cause of failure.

- Stick to a schedule: Replace bearings and seals every 12,000–15,000 miles or annually—whichever comes first.

Conclusion

The truth is simple: there’s no such thing as a reliable wheel bearing replacement trailer without a well-installed seal. Whether you’re an expert at changing bearings on trailer systems or new to trailer maintenance, recognizing the role of boat trailer bearings and seals is essential to avoiding costly failures.

By understanding the link between your bearings and your seals—and treating them as a single, interdependent system—you protect your boat, your trailer, and your investment.

Need OEM-quality parts or bulk trailer bearing and seal kits? Our company specializes in wholesale, corrosion-resistant boat trailer bearings and seals, and complete wheel bearing replacement trailer solutions tailored for marine environments. Contact us today for high-performance, long-lasting trailer components. Know More