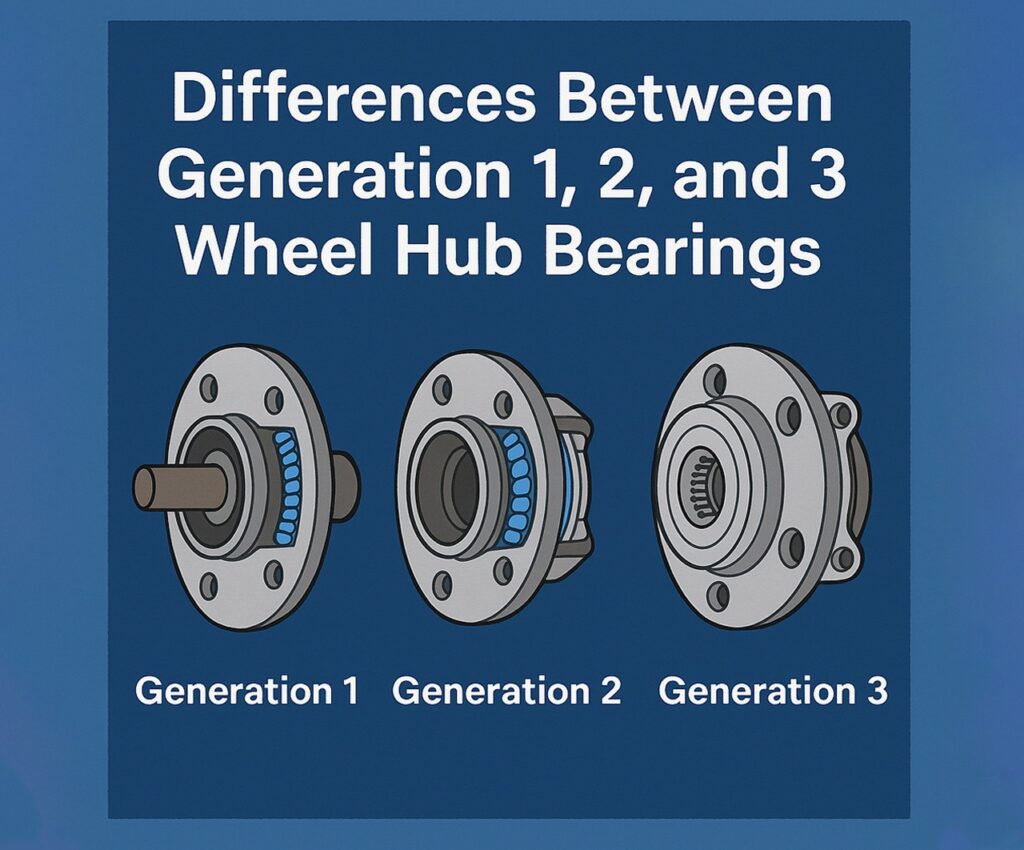

When planning a wheel hub assembly replacement, understanding the differences between hub bearing generations can help you choose the right part, reduce downtime, and optimize your repair strategy. Whether you’re trying to reduce your wheel hub replacement effort or you’re researching wheel hub replacement cost, knowing how Gen 1, Gen 2, and Gen 3 bearings differ can make a big impact on service efficiency, part compatibility, and vehicle performance. Let’s explore what sets these hub bearing generations apart and how that translates to real-world applications. Know More

What Are Wheel Hub Bearings?

Wheel hub bearings are essential components in the drivetrain of modern vehicles. They serve three main functions:

- Support the vehicle’s weight

- Enable smooth wheel rotation

- Provide a mounting point for the wheel and brake system

Over time, hub bearings have evolved to become more compact, more integrated, and easier to service—resulting in the three common generations we see today.

Generation 1: The Basic Press-Fit Bearing

Design Overview: Gen 1 bearings are the most basic hub assemblies. They consist of a double-row angular contact ball or tapered roller bearing with no integrated hub or flange. The bearing is press-fitted into the knuckle and the wheel hub is pressed into the inner race.

Installation:

- Requires a hydraulic press or special tools

- Involves separate components (bearing + hub)

- Labor-intensive

Pros:

- Lower initial wheel hub replacement cost

- Widely available for older vehicle models

- Lightweight, simple design

Cons:

- High labor cost for wheel hub assembly replacement

- Risk of damaging the bearing during press-in

- Not sealed; grease contamination or leakage possible

Common Applications:

- Older Japanese and European vehicles

- Compact cars from the 90s and early 2000s

Ideal For: Budget-conscious wheel hub replacement when time and labor are not critical constraints.

Generation 2: Integrated Hub and Bearing

Design Overview: Gen 2 bearings feature a more advanced setup where the bearing is integrated with the hub flange. The outer race is press-fit into the knuckle, but the hub and inner race come as a single unit, simplifying the replacement process.

Installation:

- Requires fewer tools

- Bolt-in or snap-ring retention in the knuckle

- Still may require a press, but to a lesser extent

Pros:

- Reduces wheel hub replacement cost by minimizing installation time

- More protection from dirt and moisture (sealed unit)

- Reduces alignment issues from improper pressing

Cons:

- Slightly more expensive than Gen 1

- Still some labor involved

- Not universally interchangeable across models

Common Applications:

- Mid-2000s sedans, SUVs, and light trucks

Ideal For: Shops and individuals wanting to save on labor without jumping to full bolt-on convenience.

Generation 3: Complete Bolt-On Wheel Hub Assembly

Design Overview: Gen 3 is the most advanced and service-friendly design. The bearing, hub, flange, and often the ABS tone ring or sensor are fully integrated into one bolt-on module. Simply remove the bolts and drop in the new wheel hub assembly replacement—no press required.

Installation:

- Fastest and easiest installation

- No special tools needed

- Preloaded and pre-sealed

Pros:

- Lowest overall wheel hub replacement labor cost

- Improved accuracy with factory preload

- Sealed for life—zero maintenance

- Includes integrated ABS components in many models

Cons:

- Higher initial part cost

- Heavier due to added components

- Not serviceable—must replace the entire assembly if anything fails

Common Applications:

- Most vehicles from 2010 onward, including trucks, crossovers, and performance cars

Ideal For: Modern vehicles where speed and reliability of wheel hub assembly replacement is crucial.

Performance and Durability Across Generations

| Feature | Gen 1 | Gen 2 | Gen 3 |

| Labor Time | High | Medium | Low |

| Tool Requirement | Press, pullers | Some tools | Basic hand tools |

| ABS Integration | External | Optional | Built-in (common) |

| Sealing | Partial | Sealed | Fully sealed |

| Serviceability | Press-out only | Partial | Non-serviceable (replacement only) |

| Wheel Hub Replacement Cost | Low parts, high labor | Moderate parts/labor | High parts, low labor |

When Should You Replace a Wheel Hub Bearing?

Regardless of generation, here are the signs your hub bearing may be failing:

- Grinding or humming noise from the wheel area

- Uneven tire wear

- ABS sensor errors (common in Gen 3)

- Excessive play or wobble when rotating the wheel by hand

- Steering vibration or pulling

Acting early can prevent damage to other suspension components and reduce total wheel hub replacement cost.

Tips for Successful Wheel Hub Assembly Replacement

- Use OE or High-Quality Aftermarket Parts Cheap bearings often lead to early failures and increased wheel hub replacement cost in the long run.

- Torque to Spec Over- or under-tightening the axle nut can destroy preload settings—especially on Gen 3.

- Clean the Hub Surface Before installing any new bearing assembly, ensure the mounting surface is rust- and debris-free.

- Replace in Pairs (When Necessary) On high-mileage vehicles, replacing both front or both rear hubs ensures balanced wear and reduces future labor costs.

Future Trends in Wheel Hub Bearings

- Sensor Integration: More Gen 3 assemblies are coming with advanced wheel speed sensors for ADAS (Advanced Driver Assistance Systems).

- Lightweight Materials: Composite and aluminum housings are being used to reduce vehicle weight.

- Smart Diagnostics: Some manufacturers are integrating diagnostics into hub units to pre-alert drivers to wear.

As vehicles become more connected and autonomous, expect even more from your wheel hub assembly replacement options.

Final Thoughts

Understanding the differences between Generation 1, 2, and 3 wheel hub bearings gives you a clearer picture of what to expect during service, both in terms of labor and wheel hub replacement cost. Whether you’re a DIYer considering a wheel hub replacement or a fleet manager planning preventive maintenance, matching the bearing generation to your performance and budget needs will help you get the most from your vehicle.

When in doubt, consult your service manual or speak with a professional technician to confirm the right part—and make your next wheel hub assembly replacement one that’s fast, smart, and long-lasting.