Engineered for Performance and Precision | High Quality P5 Stainless Steel Ball Bearing for Conveyor

The High Quality P5 Stainless Steel Ball Bearing for Conveyor is engineered to deliver top-grade motion support and long-lasting durability in material handling systems. Crafted with high-performance stainless steel and manufactured to P5 precision standards, this bearing is ideal for conveyor rollers and high-speed industrial transport lines. Its single-row deep groove design ensures quiet operation with excellent radial load capacity, making it a preferred choice for OEMs and system integrators. The bearing’s corrosion-resistant composition enhances its performance in environments exposed to moisture, chemicals, or abrasive particulates, ensuring a longer operational lifespan and reduced maintenance cycles.

Designed with a precision-ground raceway and shielded or sealed configurations (ZZ/2RS), it ensures consistent lubrication and dust exclusion for optimal performance. Whether it’s mounted in ball bearing conveyor rollers or integrated as conveyor roller end bearings, this unit supports efficient, uninterrupted motion in conveyor belts, packaging systems, and logistics hubs. Its ability to handle dynamic and static loads with minimal friction makes it the go-to bearing solution for continuous-duty cycles in both light and heavy industries.

Technical Specifications

| Attribute | Specification |

|---|---|

| Product Name | High Quality P5 Stainless Steel Ball Bearing for Conveyor |

| Applicable Industries | Manufacturing Plant, Machinery Repair Shops, Food & Beverage Factory, Farms, Retail, Printing Shops, Construction Works, Energy & Mining |

| Precision Rating | P0 – P6 |

| Material | Chrome Steel, Stainless Steel |

| Vibration Level | Z1V1, Z2V2 |

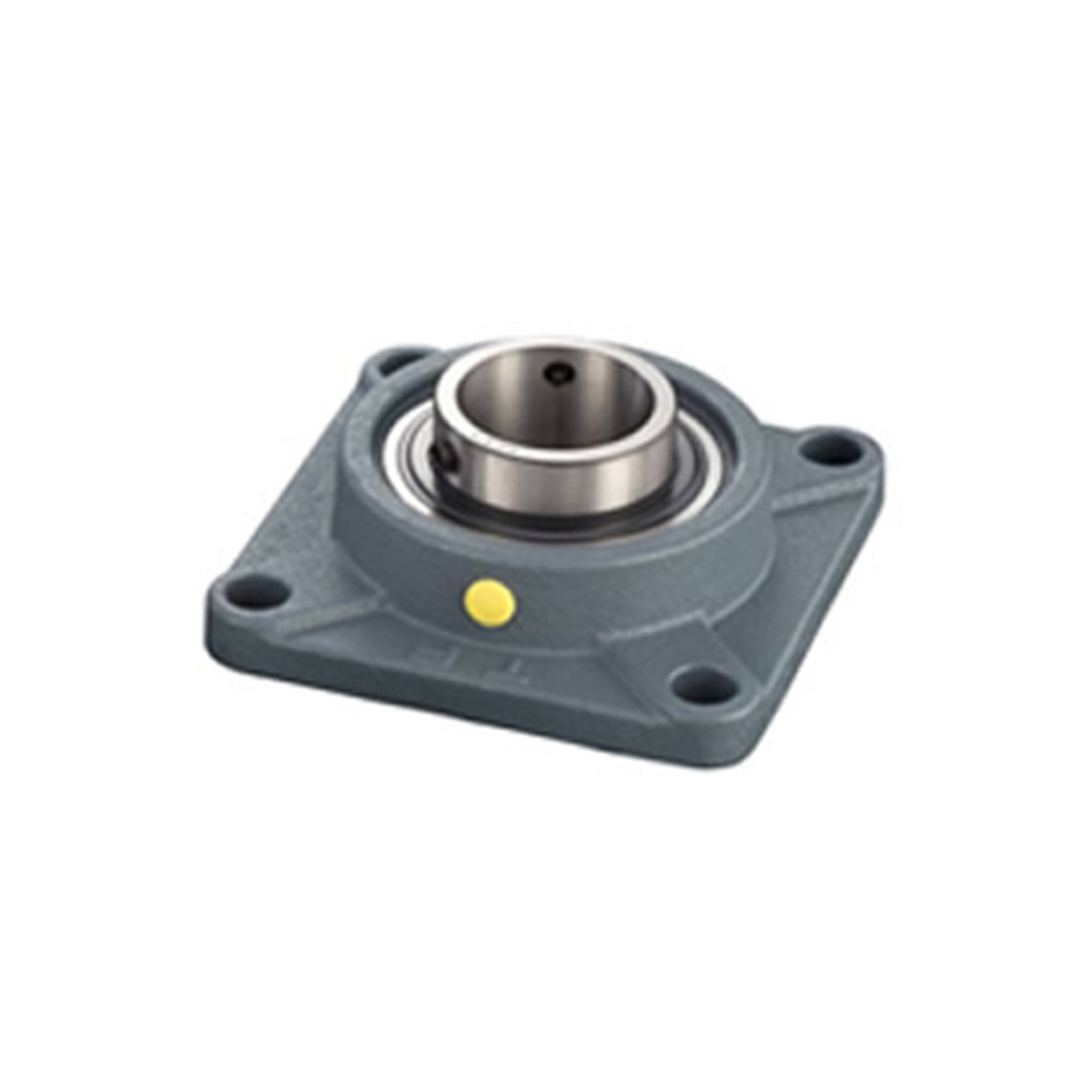

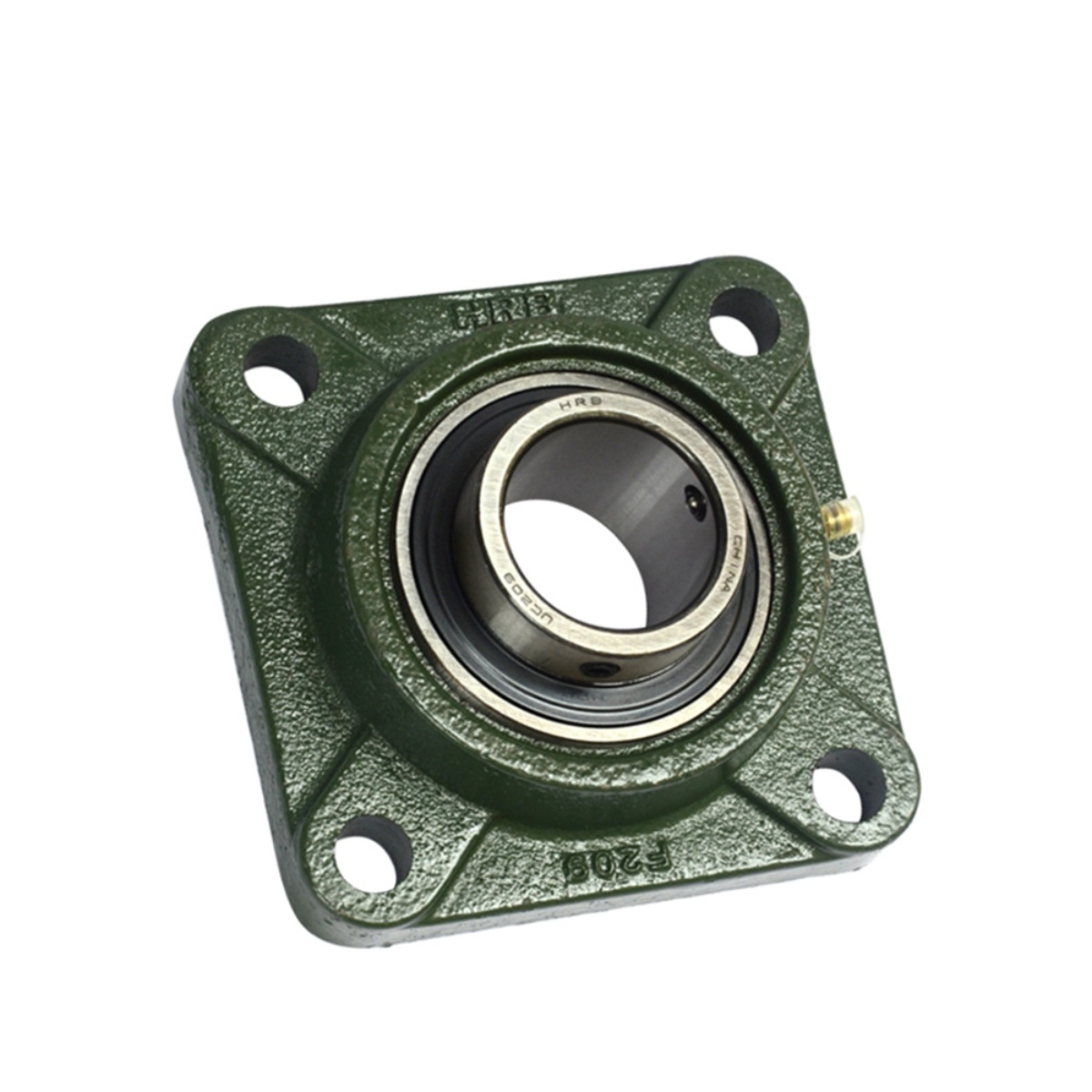

| Bearing Type | Pillow Block Bearing |

| Structure | Single Row |

| Bore Size | 8 mm – 30 mm |

| Housing Material | Cast Iron, Thermoplastic |

| Cage Type | Steel Cage |

| Seal Type | ZZ, 2RS, Open |

| Mounting Method | Bolt Mounted through Housing Base |

| Lubrication | Grease Lubricated |

| Usage | Ideal for radial load applications in rotating equipment |

| Noise Level | Low-noise operation under standard load conditions |

| Optimum Temperature | -20°C to 120°C (depending on lubrication and environmental factors) |

Why Choose High Quality P5 Stainless Steel Ball Bearing for Conveyor?

🔹 Built with P5 precision grade for enhanced rotational accuracy and vibration control

🔹 Stainless steel construction resists corrosion, rust, and contamination in humid or washdown environments

🔹 Single-row deep groove configuration offers high load-carrying capacity with low noise

🔹 Available in bore diameters ranging from 8 mm to 30 mm for broad machinery compatibility

🔹 Compatible with standard conveyor designs and ball bearing conveyor rollers

🔹 Designed for seamless fitment in conveyor roller end bearings applications

🔹 Supports both radial and limited axial loads with high-speed stability

🔹 Ideal for use in food processing, warehousing, automotive assembly lines, and distribution centers

🔹 Made from high carbon chromium steel (Chrome Steel GCR15) for inner and outer rings

Maintenance Tips for Longevity

To ensure maximum operational life of your High Quality P5 Stainless Steel Ball Bearing for Conveyor, follow best maintenance practices like routine cleaning with non-reactive solvents, timely lubrication, and secure mounting using proper tools. Bearings should be inspected for misalignment, wear, or vibration, and stored in moisture-controlled areas when not in use. Avoid high-impact installation and always check that the housing and shaft fit is within tolerance.

Order Now – Get Your High Quality P5 Stainless Steel Ball Bearing for Conveyor Today!

Upgrade your conveyor systems with the performance and reliability of P5-grade stainless steel ball bearings. Built to deliver smooth operation under continuous loads, this bearing offers unmatched durability and fitment flexibility for a wide range of conveyor applications. Don’t wait—order the High Quality P5 Stainless Steel Ball Bearing for Conveyor today and experience the engineering difference.

Reviews

There are no reviews yet.